1. Ukugeleza kwesistimu yokomisa ifilimu elincanyana

Inqubo ye-sludge medium: i-sludge emanzi ethola umgqomo + iphampu yokulethwa kwe-sludge + isomisi sefilimu esincanyana + okokusebenza okomile okomile + okomisa umugqa + isipholile somkhiqizo.

Inqubo ye-exhaust gas medium: isitimu sokuhwamuka (isitimu esixutshwe)+ ibhokisi legesi elilahlwayo + i-condenser + inkungu eqeda inkungu + isisetshenziswa esisalungiswa sefeni + esiqeda iphunga.

Udaka olusemgqonyeni wokwamukela udaka luthunyelwa ngokuqondile ukomisa ifilimu elincanyana ngepompo le-sludge screw ukuze omiswe. I-sludge yomshini wokomisa ifilimu omncane ifakwe i-valve yesango lommese womoya, exhunywe nemingcele yokulawula enengqondo yepompo yokudla, isikulufu sokuphakelayo, ukuvikela ukuphepha kwesomiso sefilimu esincanyana kanye nezinye izinto zokusebenza nezinsimbi zokubona.

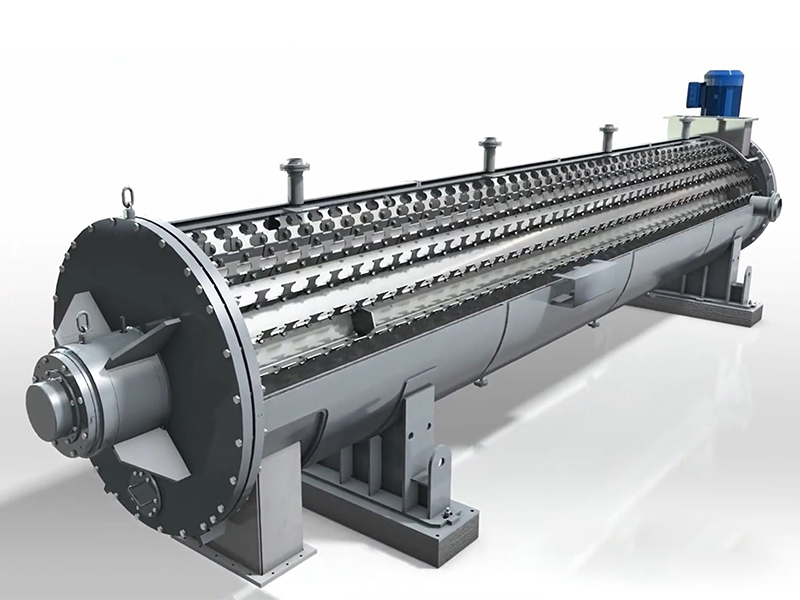

Imodeli yomzimba yokomisa ifilimu encanyana, isisindo somshini owodwa singama-33 000 kg, usayizi wenetha wezinto zokusebenza ngu-Φ1 800×15 180, ukwakheka okuvundlile nokufakwa, udaka olungena emshinini owomisa ifilimu omncane lusatshalaliswa ngokulinganayo endaweni eshisayo. udonga lwesomiso nge-rotor ngesikhathi senqubo yokujikeleza, kuyilapho i-paddle ku-rotor iphinda ixuba udaka endaweni eshisayo yodonga, Futhi phambili ekuphumeni kwe-sludge, amanzi ku-sludge ayahwamuka kule nqubo. . Izinhlayiya ze-semi-dry sludge ngemva kokoma zisuka oqweqweni oluncane zithuthwa ziyiswe esomisini esiwumugqa ngomgudu wodaka (okwenziwa kusebenze ngokuya ngesidingo sokuqukethwe komswakamo womkhiqizo wodaka), bese kungena endaweni epholile ye-sludge. Umkhiqizo we-sludge upholiswa umoya ogeleza endaweni epholile kanye namanzi okupholisa ageleza kugobolondo kanye ne-shaft ejikelezayo. Umswakamo uncishiswa usuka ku-80% uye ku-35% (umswakama wodaka ongama-35% uwumkhawulo ongaphezulu wokulawula wento eyodwa yokomisa ifilimu).

Igesi elithwalayo elikhishwa esomisweni sefilimu elincanyana liqukethe umhwamuko omningi wamanzi, uthuli nenani elithile legesi eguquguqukayo (ikakhulukazi i-H2S ne-NH3). Uma ikhishwa ngokuqondile, izodala izinga elithile lokungcoliswa kwemvelo. Ngakho-ke, le phrojekthi icubungula uhlelo lokuqoqa igesi yenethiwekhi kanye ne-condenser nenkungu ukususa uthuli kanye nomhwamuko wamanzi kugesi wokuphuma, okuphambene nokuqondisa kokunyakaza kodaka kusilinda esijikelezayo. I-exhaust gas pipe outlet ngaphezu kwe-sludge ingena ku-condenser, futhi amanzi apholiswa phansi kusukela ku-evaporation gas exhaust. Ngokushintshana kokushisa okungaqondile, amanzi okufuthwa asuswa isishintshi sokushisa sepuleti nombhoshongo wokupholisa, ukuze kongiwe amanzi futhi kuncishiswe ukuchithwa kwendle. Igesi engaconsi (inani elincane lesitimu, i-N2, umoya nodaka) idlula ku-demister. Okokugcina, ifeni esalungiswa ebangelwa kuphelelwa amandla iyakhishwa ohlelweni lokumisa ukuya kudivayisi yokuqeda iphunga.

Isidingo somthombo wokushisa sinqunywa njengesitimu, esithathwa kunethiwekhi yepayipi elimboza ukushisa elakhiwe eduze nendawo yokuqaliswa kwephrojekthi. Izimo zokunikezwa kwesitimu ukucindezela kwesitimu esingu-1.0MPa, izinga lokushisa lesitimu elingu-180 ℃ kanye nokunikezwa kwesitimu okungu-2.5t/h.

2. Imingcele yezobuchwepheshe yemishini eyinhloko yenqubo yokumisa ifilimu emincane

Ngokwesidingo sale phrojekthi, umthamo wokwelapha udaka lwesethi eyodwa yesistimu yokomisa udaka kunqunywa ukuthi ube ngu-2.5t/h(ngokokuqukethwe komswakama okungama-80%), kanti umswakama wodaka ungama-35%. Umthamo wansuku zonke wokwelapha udaka esomiso sefilimu esincanyana esisodwa singama-60 t/d(ngokokuqukethwe komswakama okungama-80%), umthamo wokuhwamuka olinganiselwe wesomisi sefilimu esincanyana esisodwa ngu-1.731 t/h, indawo yokushintshanisa ukushisa kwento eyodwa. isomisi sefilimu esincanyana singama-50 m2, kanti umswakama wokungena kodaka ungama-80%, kanti umswakama wokukhipha udaka ungama-35%. Umthombo wokushisa womshini wokomisa ifilimu omncane ugcwele isitimu, kanti izinga lokunikezwa kwesitimu lifakwa emazweni angaphandle: izinga lokushisa lesitimu lingu-180 ℃, umfutho we-steam ngu-1.0 MPa, ukusetshenziswa kwesitimu kwesomiso sefilimu esincanyana esisodwa kungu-2.33t/h, kanti inombolo yokomisa ifilimu emincane ngu-2, eyodwa yokusetshenziswa okukodwa.

Isitimu esigcwele esingu-180 ℃ sithuthelwa ukomisa ulayini ngepayipi lokucindezela, futhi sisetshenziswa njengomthombo wokushisa ukushisisa ngokungaqondile udaka olomile. Amanzi odaka olomile aphinde ahwamuke esomisweni esiwumugqa. Ngokwesidingo sangempela somkhiqizo we-sludge (qala futhi ume), i-sludge yokugcina ingafinyelela umswakama ongu-10% futhi iye endaweni epholile yomkhiqizo.

Umthamo wokucubungula we-linear dryer ngu-0.769t / h(umswakama 35%), ukuhwamuka okulinganiselwe ngu-0.214t / h, indawo yokushintshanisa ukushisa ingu-50 m2, okuqukethwe komswakama kwe-sludge inlet ye-linear dryer kungu-35%, umswakama. Okuqukethwe kokukhipha udaka ngu-10%, izinga le-steam lokungena endaweni yokomisa engulayini: Izinga lokushisa lesitimu lingu-180 ℃, umfutho we-steam ngu-1.0 MPa, ukusetshenziswa kwesitimu kwesomiso esiwumugqa owodwa ngu-0.253 t/h, futhi inani lihlonyelwe ngesethi engu-1.

Uhlobo lwensiza ye-condenser yegesi ethwala igesi i-direct injection hybrid condenser, edonsa umoya ongu-3 500 Nm3/h, izinga lokushisa legesi elingenayo elingu-95~110 ℃, izinga lokushisa legesi eliphuma ngaphandle elingu-90~180 Nm3/h, kanye negesi yokuphuma. izinga lokushisa ngu-55 ℃.

Uhlobo lwemishini yesiphathimandla segesi yokusalungiswa eyenzelwe i-fan yokucindezela okuphezulu yi-fan ye-centrifugal ephezulu, ivolumu ephezulu yokumunca umoya ngu-400 Nm3/h, ingcindezi yomoya ingu-4.8 kPa, imingcele ebonakalayo yesiphathimandla segesi: izinga lokushisa ngu-45 ℃, umswakama. ingu-80% ~ 100% ingxube yegesi yephunga lomoya omanzi, isethi eyodwa yesistimu yokomisa ifakwe isethi engu-1.

Umthamo wokucubungula we-cooler yomkhiqizo ngu-1.8t / h, izinga lokushisa le-sludge inlet liyi-110 ° C, izinga lokushisa le-sludge liyi-≤45 ° C, indawo yokushintshanisa ukushisa yi-20 m2, kanti ubuningi buyiyunithi engu-1.

3. Ukuhlaziywa kokusetshenziswa kwamandla kwezomnotho ngesikhathi sokusetshenziswa kwesomisi sefilimu esincanyana

Ngemva cishe kwesigamu senyanga sokugunyazwa okukodwa kanye nokufakwa kodaka ohlelweni lwenqubo yokomisa ifilimu emincane, imiphumela imi kanje.

Umthamo wokucubungula ukumisa umklamo wesomiso sefilimu esincanyana esisodwa kule phrojekthi ungu-60 t/d. Njengamanje, isilinganiso sokwelashwa kodaka olumanzi ngesikhathi sokugunyazwa singama-50 t/d(umswakama ongama-79%), osefinyelele ku-83% esikalini esiklanyelwe sokwelashwa kwesisekelo esimanzi kanye nama-87.5% esikalini esiklanyelwe sokwelapha isisekelo sodaka.

Isilinganiso somswakama wodaka oluyi-semi-dry sludge olukhiqizwe isomisi sefilimu esincanyana singama-36%, kanti umswakama wodaka olomile oluthunyelwa kwamanye amazwe yisomiso esiwumugqa singama-36%, ngokuyisisekelo uhambisana nenani elihlosiwe le-semi-dry sludge. umkhiqizo wokuklama (35%).

Kukalwa imitha yesitimu egcwele yangaphandle endaweni yokusebenzela yokomisa udaka, ukusetshenziswa kwesitimu esigcwele kungu-25 t/d, futhi ingqikithi yokushisa esetshenziswa nsuku zonke yokushisa okucashile kokuhwamuka kwesitimu kungu-25 t×1 000×2 014.8 kJ/kg÷4.184 kJ =1.203 871 9×107 kcal/d. Isilinganiso sansuku zonke samanzi ahwamukayo sansuku zonke wesistimu yokomisa si (50 t × 0.79)-[50 t ×(1-0.79)]÷(1-0.36)×1 000=23 875 kg/d, Bese ukusetshenziswa kokushisa kweyunithi uhlelo lokumisa udaka luyi-1.203 871 9×107÷23 875=504 kcal/kg amanzi ahwamukile; Ngenxa yokuthi uhlelo lokumisa udaka lungaphansi kokushintshwa komswakama wodaka olumanzi, ikhwalithi yesitimu sangaphandle, kanye nezici zemishini yokuthutha umkhiqizo we-semi-dry sludge ngezidingo ze-granularity nezinye izici, kuyadingeka ukwandisa inani lokuhlukahluka okuhlukahlukene. ekusebenzeni kwesilingo sesikhathi eside esizayo, ukuze kufinyezwe izimo zokusebenza ezingcono kakhulu kanye nenkomba yokusetshenziswa kwamandla kwezomnotho yesistimu.