Classification of electrostatic precipitator

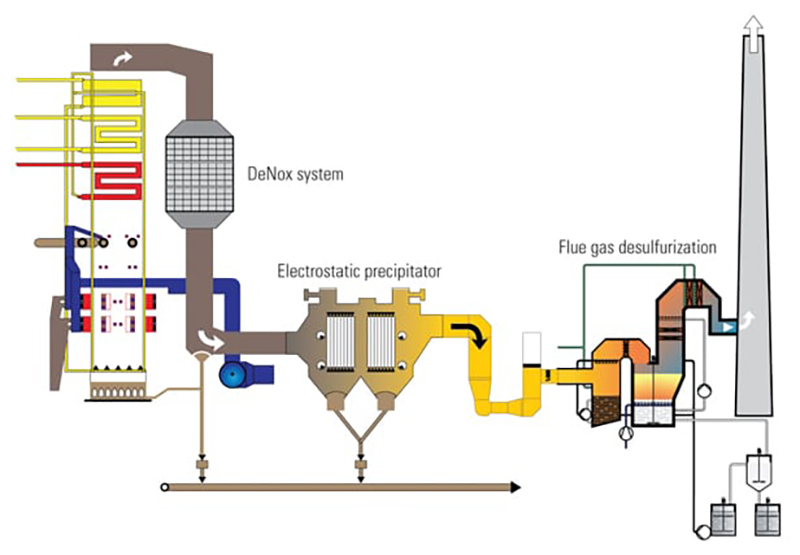

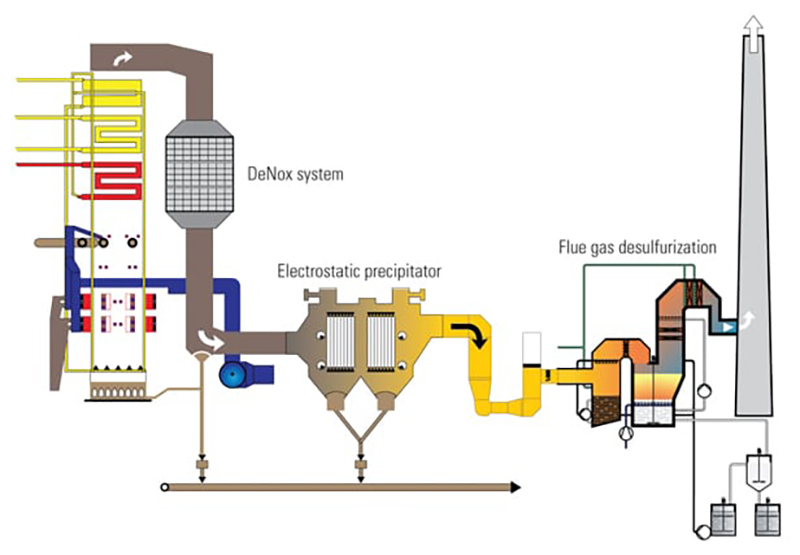

According to different cleaning methods can be divided into dry electrostatic precipitator, wet electrostatic precipitator, fog particle electrostatic collector and semi-wet electrostatic precipitator.

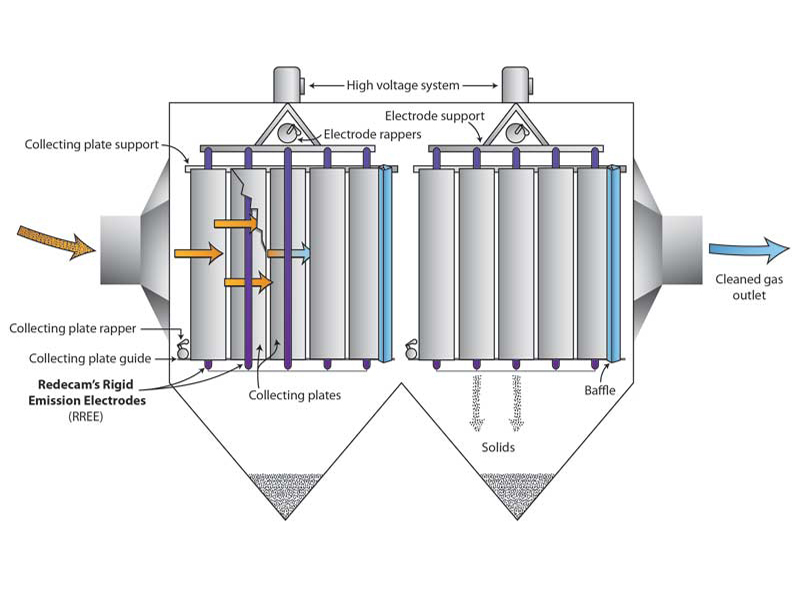

(1) Dry electrostatic precipitator: the dust in the flue gas is captured in the dry state, and the dust deposited on the dust collecting board is cleaned by mechanical vibration and electromagnetic vibration.

(2) Wet electrostatic precipitator: for the dust collected by the dust collecting pole, water spray overflow or use the appropriate method to form a layer of water film on the surface of the dust collecting pole, so that the dust deposited on the dust collector and water flow together to the lower part of the dust collector to discharge, using this cleaning method is called wet electrostatic precipitator.

(3) Fog particles electrostatic defogger: Use electrostatic precipitator to capture droplets like sulfuric acid fog and tar fog, and then flow down in liquid state after capture and remove.

(4) Semi-wet electrostatic precipitator: both dry electrostatic precipitator and wet electrostatic precipitator advantages, there is a dry, wet mixed electrostatic precipitator, also known as semi-wet electrostatic precipitator; The structure system is that the high temperature flue gas is first discharged through two dry dust removal chambers, and then through wet dust removal chambers through the chimney.

Classification of electrostatic precipitator

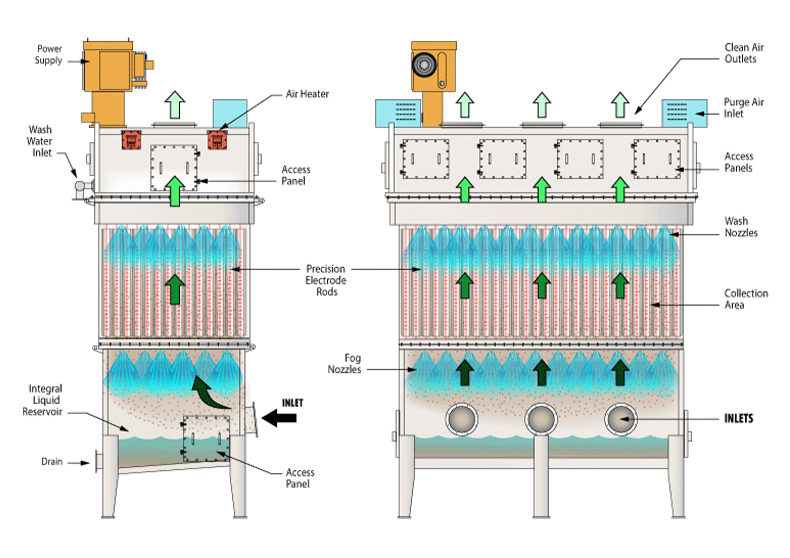

Wet electrostatic precipitator (also known as wet electric dust collector) works as follows:

1. At the beginning of the process, particulate matter with static electricity is entered into the air flow of the wet electrostatic precipitator.

2. The air flow first passes through a water spray chamber where the spray captures and humidifies particles in the air.

3. The spray adsorbs particles from the air to the water droplets, making them heavy and sink to the bottom.

4. They are in contact with the water in the bottom sedimentation tank, thus being completely separated from the air flow.

5. Electrostatic field is used to enhance the dust removal effect. In a wet electrostatic precipitator, the spray particles used by an electrostatic generator to the water spray chamber have a static charge.

6. Particles attached to water droplets with electrostatic charges are more effectively attached to water droplets by electrostatic forces and by wetting surfaces with greatly increased concentrations.

7. The water droplets after electrostatic treatment are reabsorbed into the sedimentation tank, and the concentration of particulate matter has been reduced before the air passes through the dust collector.

8. The cleaned air is released into the environment, thus achieving the dust removal effect.

The working principle of wet electrostatic precipitator mainly relies on the combination of water spray and electrostatic effect to separate particles from the air and effectively purify the air.

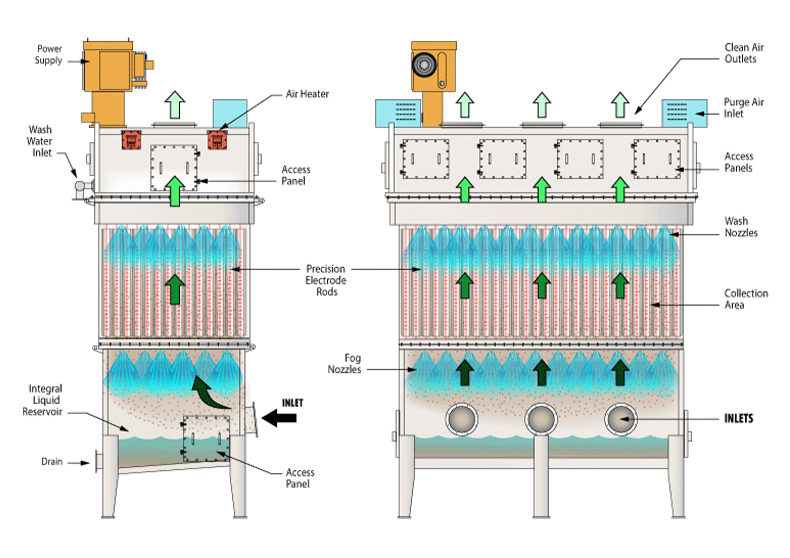

Wet electrostatic precipitator is a kind of secondary dust removal equipment added after wet desulphurization. Wet electrostatic precipitator is a new dust removal equipment used to deal with trace dust and micro-particles, which is mainly used to remove dust, PM2.5, aerosol, odor, acid fog, water droplets and other harmful substances in wet gases, and is an ideal equipment for controlling atmospheric dust pollution.

Wet electrostatic precipitator is mainly composed of inlet and outlet flue, precipitator house body, deflector plate, rectifier grid, anode dust collecting plate cathode line, insulation box, flushing water system, power supply and control system. The type of structure is generally divided into two types: plate and tube. The dust collection of plate is very flat, the formation of water film is good, the corona line is distributed between plates, and the main body is similar to a dry electrostatic precipitator, which can handle the flue gas in a degree or straight movement. The tubular dust collecting pole is generally a circular or polygonal metal tube in parallel, and the corona line is distributed in the middle, which can only handle the straight moving smoke. The external components of the wet electrostatic precipitator adopt ordinary carbon steel, and the inner surface is coated to prevent corruption. When installing the device, attention should be paid to the damage of the inner surface, especially the welding points and the joints of the components.

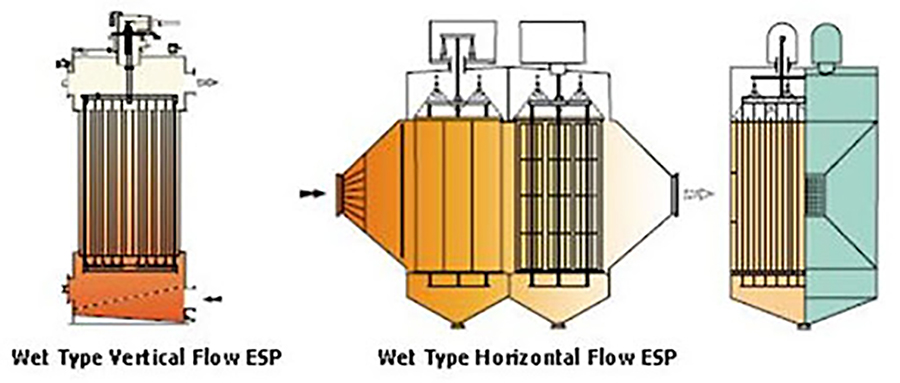

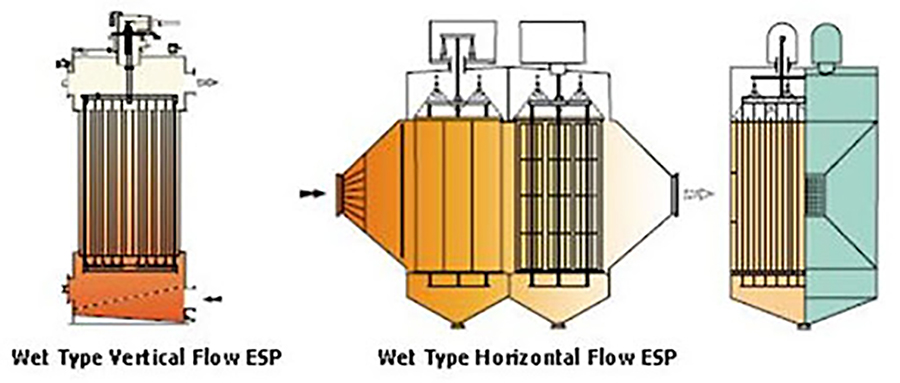

Wet electrostatic precipitator has two main structural forms, one is the use of corrosion-resistant conductive materials as a dust collector, the other is the use of water spray or overflow water to form a conductive water film, the use of non-conductive non-metallic materials as a dust collector, of course, can also be divided into cross-flow and vertical flow according to the flow of waste gas, cross-flow type is mostly plate structure, gas flow direction for horizontal in and out. The structure is similar to a dry electrostatic precipitator, the vertical flow is mostly tubular structure, and the gas flow is in and out of the vertical direction.

Wet electrostatic precipitator can be divided into cross-flow type and vertical flow type. Under the same ventilation cross-sectional area, the dust removal efficiency of the vertical flow wet precipitator is twice that of the cross-flow type.

Composition of wet electrostatic precipitator

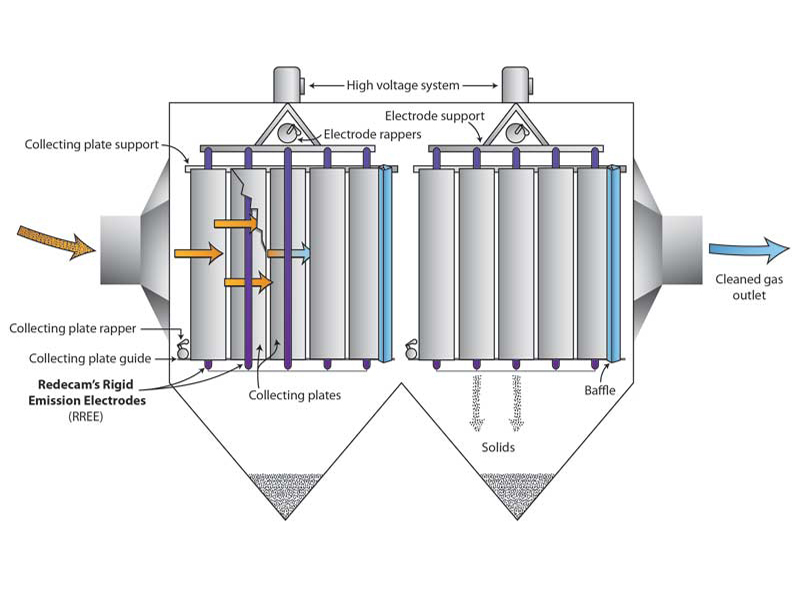

Wet electrostatic precipitator (WESP) is mainly composed of the structure body, cathode system, anode system, atomization flushing system, water treatment system, electric control system, etc. (see figure). The WESP body is basically the same as that of dry ESP, including inlet horn, outlet horn, shell, discharge electrode and frame, collector insulator, atomizing nozzle and pipeline.

(1) Cathode system:The cathode system is composed of a cathode bearing beam, a cathode line, a heavy weight and a lower cathode frame. The upper end of the cathode line is hung on the cathode bearing beam, and the lower end is combined with the cathode line and a heavy weight. The selection principle of the cathode wire is durable, low corona voltage, strong discharge, high corona current density, good rigidity, root resistance, strong chloride ion corrosion resistance (such as lead-antimony alloy materials). The sawtooth line is usually used as the discharge electrode to meet the requirements of fine dust charging. Selection parameters of different cathode lines.

(2) Anode system:The anode system uses a special anode plate (tube) structure to meet the operating requirements of atomization spray and washing. For vertical wet electrostatic precipitator, most of the current anode systems use hexagonal conductive and flame retardant glass fiber reinforced plastic tube bundles arranged as dust collection poles. The honeycomb electrode is composed of hexagonal CFRP honeycomb tubes with an internal tangent circle of φ350mm/360mm, wall thickness of 3mm and length of 6000mm, and is suspended on the support beam of the tube bundle.

(3)Atomizing and washing system:The atomizing and washing system is generally installed on the upper part of the wet and electrostatic precipitator. The atomizing water droplets enter the WESP wet electrostatic precipitator work area with the flue gas, and tend to the dust collecting electrode under the action of electric field, and form a water film on the dust collecting electrode. Under the action of gravity, the droplets are carried into the water collection tank or desulfurization tower. Fog droplets have several important effects on the efficiency of electrostatic precipitator dust removal.

1. The fog drops can keep the discharge electrode clean, so that the corona has been strong: the fog drops hit the dust collecting pole to continuously form a thin and uniform water film, which can prevent the "secondary flying" of low specific resistance dust, adjust the high specific resistance dust to prevent the "anti-corona" phenomenon, prevent the strong viscosity of the dust sticking to the electrode, and is suitable for collecting flammable and explosive dust.

2. The droplet is directly sprayed to the discharge electrode and corona area, and the discharge electrode can also play the role of the atomizer. The same power supply can realize corona discharge, water atomization, water mist and dust particle charging, and realize the organic combination of static electricity and water mist.

3. The droplets are directly sprayed to the discharge electrode, and the charge is high, which can greatly improve the dust removal efficiency than the collision interception and absorption plate of atomized water in the electric field.

4. Spray the droplets to the discharge electrode and corona area to further atomize the water mist. There is no direct contact between static electricity and the atomizing spray device, and there is no insulation problem.

5. The burr electrode can produce a strong electrostatic field, and has a good corona discharge ability, and the electrostatic and fog droplet synergy. It has high dust removal efficiency.

6. The droplets form water flow on the dust collecting pole, so that the dust collecting pole (pipe) is always clean, eliminating the vibration device, and avoiding the secondary pollution caused by dry dust removal due to the vibration cleaning.

(4) Water treatment system: The water treatment system includes circulating water tank, circulating water pump, drainage water tank, drainage water pump, alkali storage tank, alkali metering pump, industrial water tank, industrial water pump and corresponding pipelines. After spraying and dusting, the collected liquid is first collected in the drainage tank, and then added to the NaOH solution to adjust the pH value, and then discharged to the desulfurization system as supplementary water. The other water is overflowed to the circulation tank through the drainage tank. The circulating water in the circulating water tank is configured with a pH value of 8 ~ 10 by adding industrial water and lye, which is used as the circulating water of the wet electrostatic precipitator and is returned to the atomizing nozzle. The water lost by external discharge is supplemented by industrial water.

(5) Electric control system: The electric control system of WESP wet electrostatic precipitator consists of two parts: low voltage control system and high voltage control system. The electrical load mainly includes the WESP precipitator body, insulated box heating device, water pump and so on. The low-voltage control system is used for the power distribution control of the insulated box heater, equipped with a PLC control system, which is used to realize the automation of the insulated box heater, so that the temperature of the insulated box is always maintained at 100~120℃; The high voltage control system is mainly a high voltage control cabinet and a high voltage generator, which provides power for the corona electrode device to form a corona field and achieve deep purification of the flue gas.

To sum up, the components of the wet electrostatic precipitator are complex and diverse, and each component plays an important role. The electrostatic precipitator unit, water circulation system, ventilation system and control system cooperate with each other to complete dust removal and air purification. The collaborative work of these components makes the wet electrostatic precipitator an efficient and reliable air pollution control equipment.

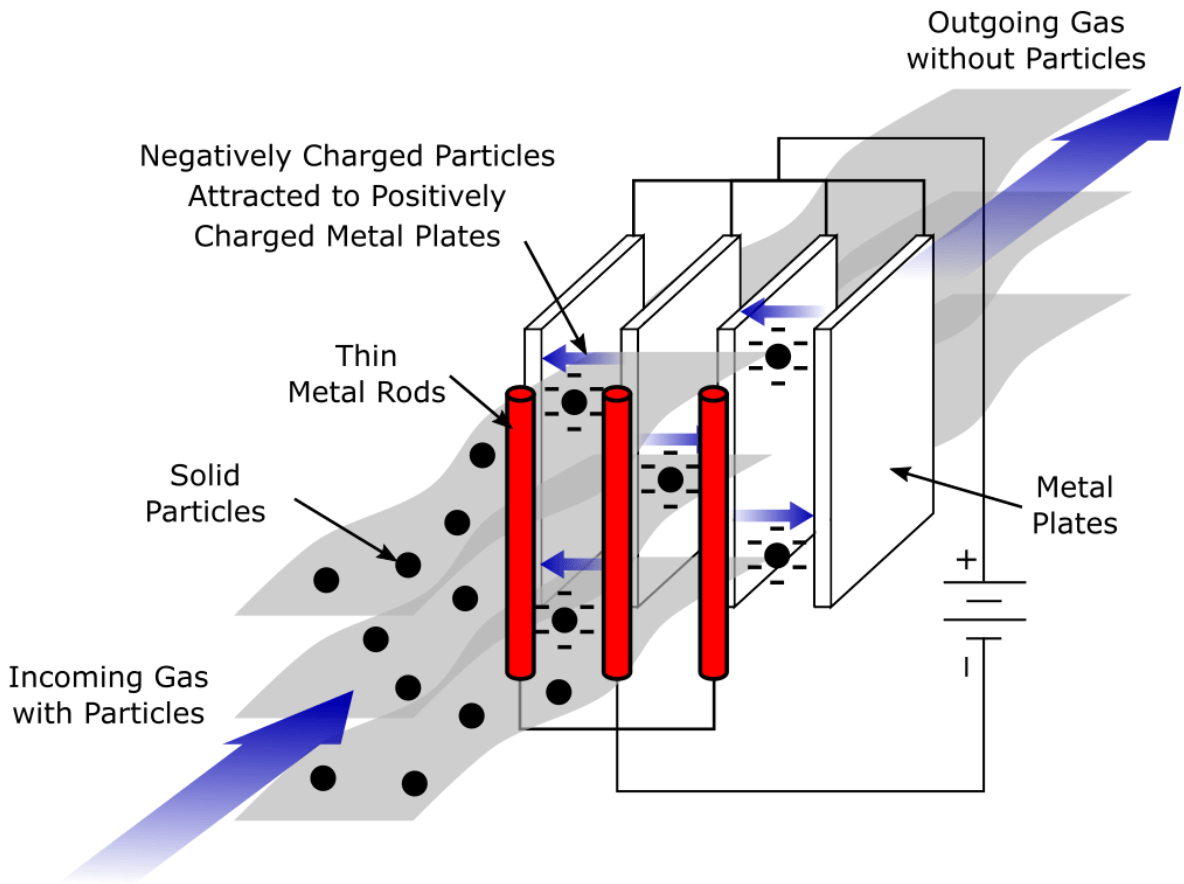

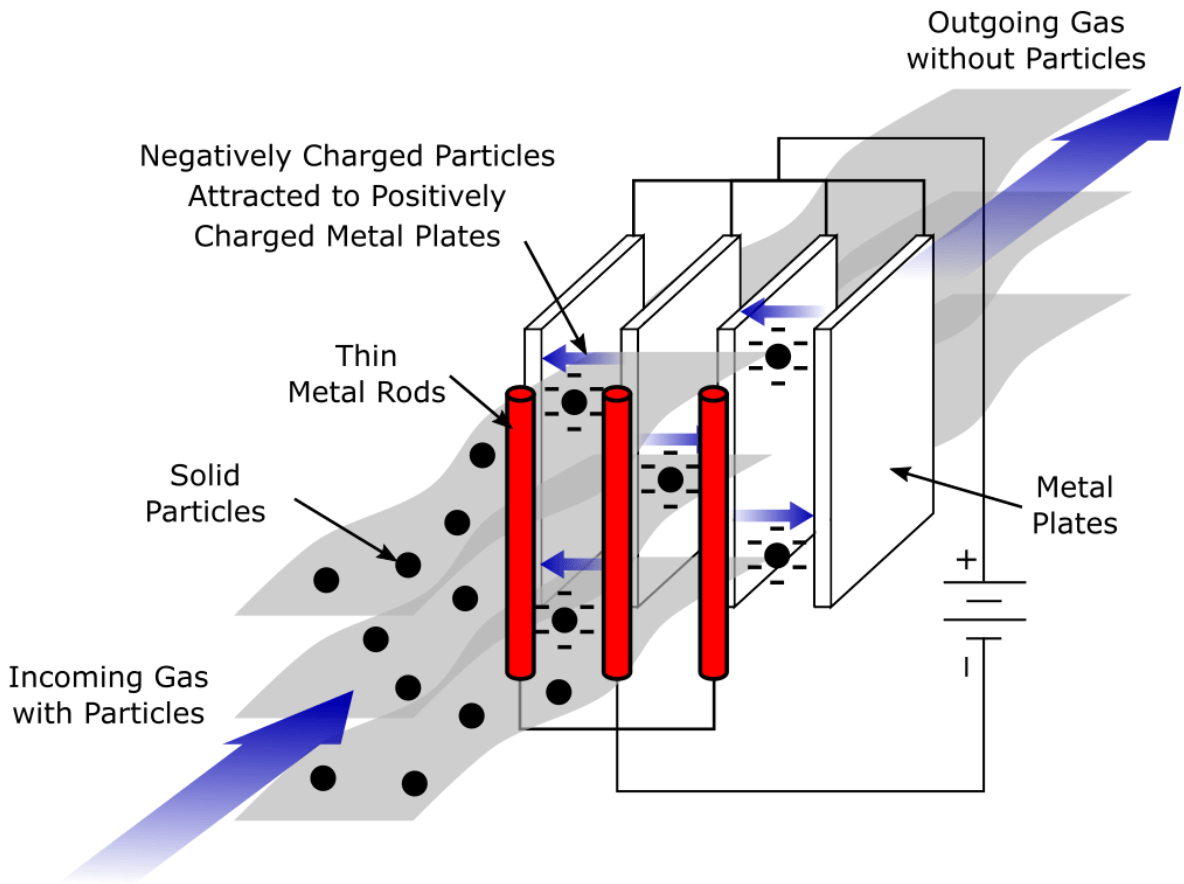

The working principle of electrostatic precipitator

The working principle of electrostatic precipitator is to use high voltage electric field to ionize the flue gas, and the dust charged in the air stream is separated from the air stream under the action of the electric field. The negative electrode is made of metal wire with different section shapes and is called discharge electrode. The positive electrode is made of metal plates of different geometric shapes and is called the dust collecting electrode. The performance of electrostatic precipitator is affected by three factors, such as dust properties, equipment structure and flue gas velocity. The specific resistance of dust is an index to evaluate the electrical conductivity, which has a direct influence on the efficiency of dust removal. The specific resistance is too low, and it is difficult for dust particles to remain on the dust collecting electrode, causing them to return to the air stream. If the specific resistance is too high, the dust particle charge reaching the dust collecting electrode is not easy to release, and the voltage gradient between the dust layers will cause local breakdown and discharge. These conditions will cause the efficiency of dust removal to decline.

The power supply of electrostatic precipitator is composed of control box, booster transformer and rectifier. The output voltage of the power supply also has a great influence on the dust removal efficiency. Therefore, the operating voltage of electrostatic precipitator should be kept above 40 to 75kV or even 100kV.

Compared with other dedusting equipment, electrostatic precipitator has less energy consumption and high dust removal efficiency. It is suitable for removing 0.01-50μm dust in the flue gas, and can be used for occasions with high flue gas temperature and high pressure. The practice shows that the larger the gas volume treated, the more economical the investment and operation cost of electrostatic precipitator.

Factors affecting the performance of electrostatic precipitator

The performance of electrostatic precipitator is affected by three factors, such as dust properties, equipment structure and flue gas velocity. The specific resistance of dust is an index to evaluate the electrical conductivity, which has a direct influence on the efficiency of dust removal. The specific resistance is too low, and it is difficult for dust particles to remain on the dust collecting electrode, causing them to return to the air stream. If the specific resistance is too high, the dust particle charge reaching the dust collecting electrode is not easy to release, and the voltage gradient between the dust layers will cause local breakdown and discharge. These conditions will cause the efficiency of dust removal to decline. Electrostatic precipitator is suitable for gas treatment with relatively thin dust concentration, and other dust removal equipment needs to be considered for high concentration dust problems.

1. Condensation: If condensation is caused by controlling the thermodynamic properties of the flowing gas flow, the particles can play the role of growing nuclei in the condensation process. Particles that are then coated with liquid are more easily trapped by the important trapping mechanism described above. Condensation is usually obtained by condensing the vapor condensate at a lower pressure to a higher pressure, introducing steam into the saturated flow, or/and directly cooling the flow.

2. Obstruction: If a small particle moves around an obstacle in the fluid, it may come into contact with the obstacle due to the relatively large physical size of the particle. This also occurs in the relative activity of dust particles and droplets.

3. Inertial impact: If the particles are evacuated in the flowing gas, when the flowing gas encounters an obstacle, the inertia will make the particles break through the gas flow around the obstacle, and some of the particles will hit the obstacle. The likelihood of such an event depends on several variables, in particular the magnitude of the inertia of the particles and the size of the obstacle (in the case of wet precipitators, the obstacle is the droplet). In a dust collector, inertial impact is generated between dust particles and relatively large droplets.

4. Electrostatic charging: When there are different electrostatic charges between particles and droplets, it will be more effective to combine dust particles and droplets. The electrostatic scrubber uses this mechanism to enhance the attraction of dust and water droplets and thus improve the dust collection efficiency.

5. Diffusion: Small particles with an aerodynamic particle size of less than 0.3μm(specific gravity of 1) are important to capture by diffusion, because their small mass is unlikely to produce inertial impact, and their small physical size is not easy to be blocked. The process by which small particles move from areas of high concentration to areas of low concentration is called diffusion. Diffusion is important as a result of Brownian activity, the random movement of tiny particles as they collide with surrounding gas molecules and other particles. When these particles are trapped in a droplet, the concentration of particles in the area near the droplet decreases, and other particles once again move from the area of high concentration to the area of low concentration near the droplet.

Daily maintenance of electrostatic precipitator

1. Strictly monitor the primary voltage, primary current, secondary voltage and secondary current of the power supply device. Record once every 1 hour.

2. Monitor the temperature rise of high-voltage silicon rectification, the oil temperature shall not exceed 80 ° C, no abnormal sound, and no abnormal discharge phenomenon in the high-voltage output network.

3. Each incubator and ash hopper heater work normally.

4. The control devices on the control cabinet work normally.

5. The operation of the ash discharge system should be understood every hour.

6. Often check the spark rate within the specified range, if found not meet the requirements, should be adjusted in time, so that the dust collector in a good running state.

7. When the dust collector and auxiliary equipment fail or misoperate during normal operation, the operator shall immediately go to confirm the fault point, analyze the cause, and contact for treatment after receiving the alarm notification.

8. Each shift should conduct a comprehensive inspection of the equipment of electrostatic precipitator, and do a good job of cleaning work within the jurisdiction of the post, record in detail the abnormal situation and equipment defects occurred in the operation of the shift, and do a good job of shift handover.

9. Motor, reducer, bearing and all external moving parts should be checked twice per shift, each lubrication point should be regularly checked lubrication, if necessary, should increase lubricating oil or grease.

10. Check whether the silicone used for drying is discolored, and it should be replaced in time when it is discolored.