Screw Decanter Centrifuge Sewage Sludge Dewatering Treatment Plants Water-solid-oil Separation

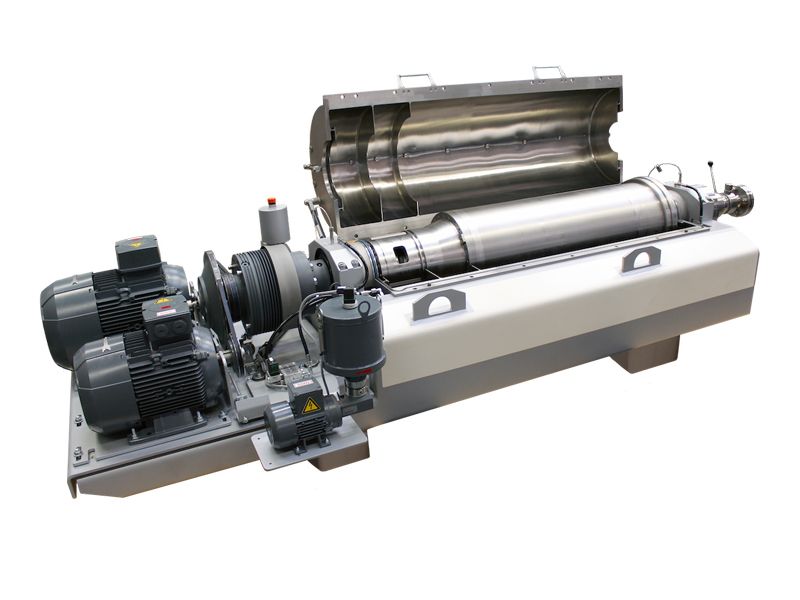

Product Feature

Working principle of screw decanter centrifuge machine

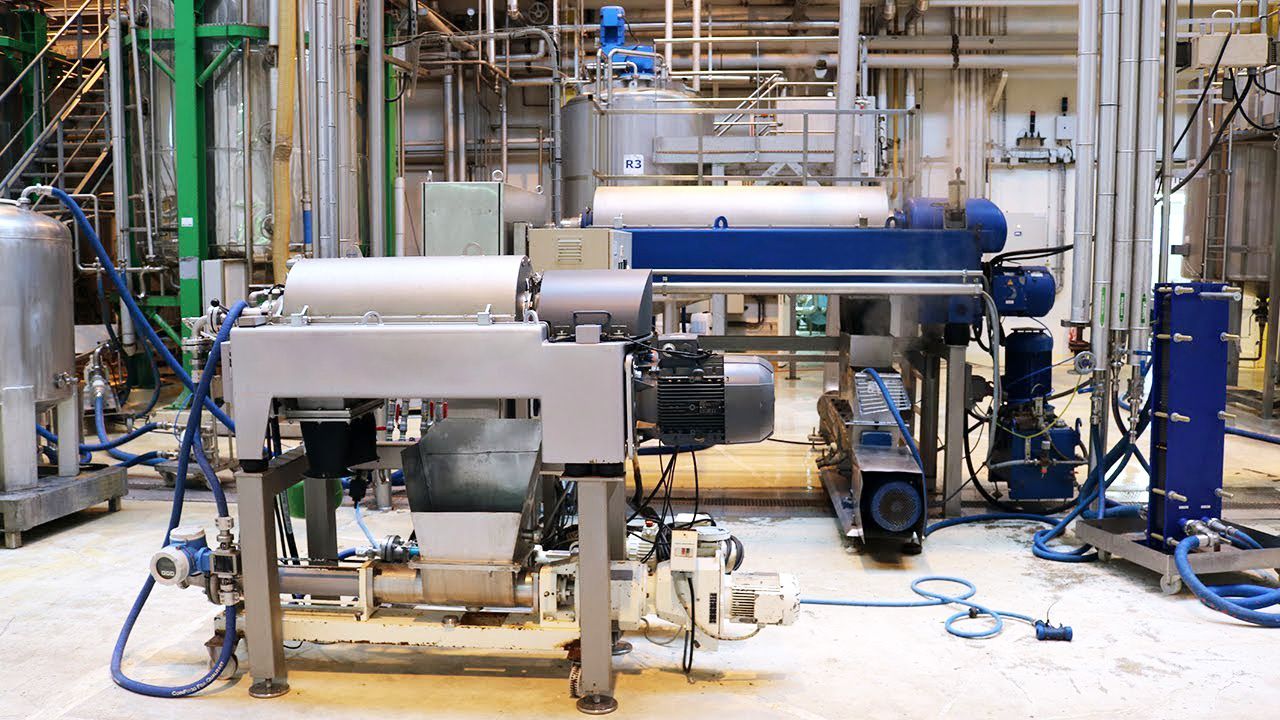

In terms of environmental protection applications, decanter centrifuges mainly refer to the dewatering of sludge generated in the process of industrial and civil sewage treatment. Today's environmental problems have become the focus of common concern all over the world. In this context, the value of decanter centrifuge has been reflected. In the past, sewage plants or related treatment plants have used self-sedimentation or belt filter press to dewater and concentrate sludge. Sludge moisture content from 98% to 80%, its volume can be reduced by 10 times, because of this, decanter sedimentation centrifuge because of its inherent processing capacity, automatic operation, good dehydration effect and other characteristics, in the field of environmental protection has been widely used and promoted. Screw Decanter centrifuge single product sales accounted for about half of all centrifuge products, laying its irreplaceable position. Screw Decanter centrifuge is preferred for sewage treatment equipment.

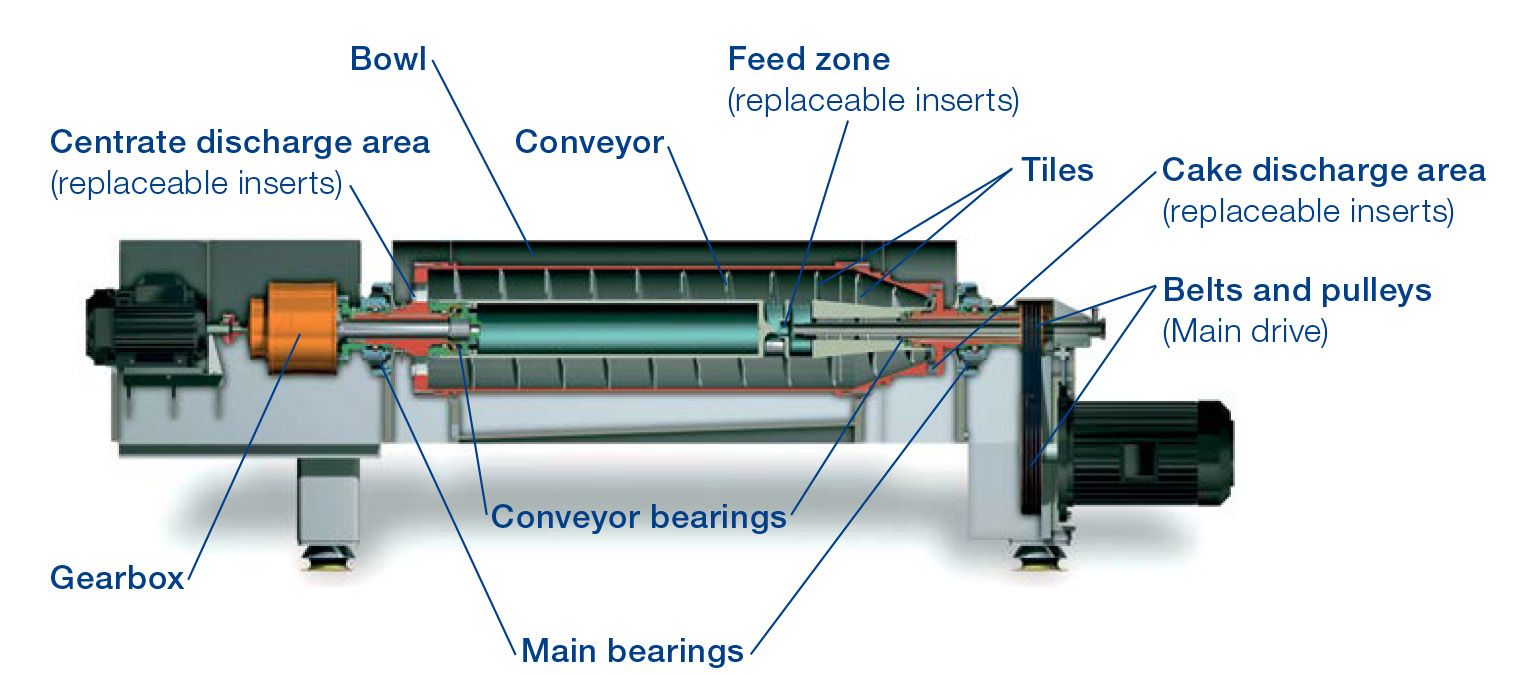

Structure of screw decanter centrifuge equipment

Characteristics of screw decanter centrifuge

Decanter type centrifugal dehydrator parameters details

description2