Paddle Sludge Dryer Machine Equipment Sewage Slurry Drying Treatment Process System

Project Introduction

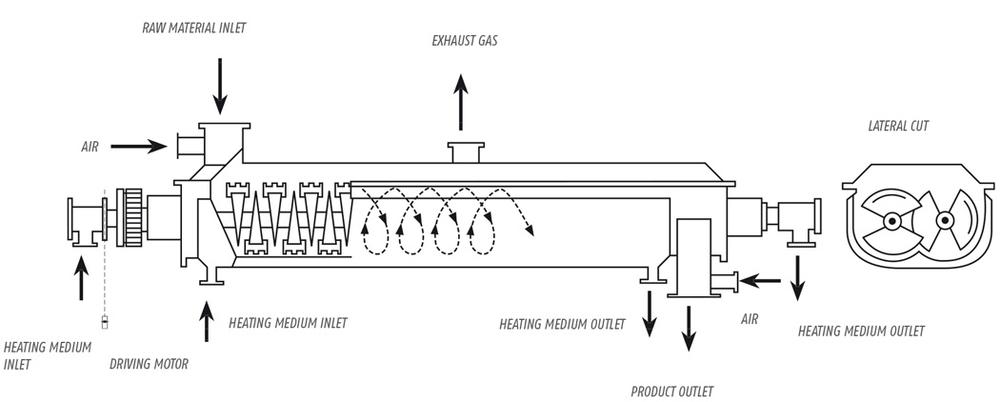

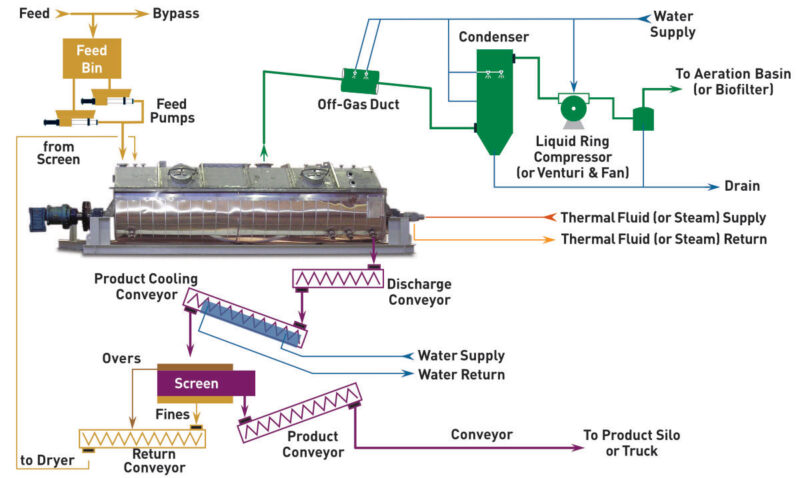

The heating medium flows through the casing jacket and the hollow stirring shaft through the rotating joint, and the material is heated and dried by conduction heating. The structure of the hollow paddle shaft of different materials is different to ensure better heat transfer effect. The material is added by the feeding port, and the interface is updated under the stirring action of the two hollow paddle shafts. At the same time, the material is promoted to the discharge port, and the dried material is discharged by the discharge port.

Project Introduction

3.The bearing body of the paddle sludge dryer is another key component, with two or three bearing bodies installed at both ends. These bearing bodies consist of bearings, bearing seats, bearing caps, sealing packings, packing glands and inspection covers. They play a vital role in supporting the spindle and ensuring smooth operation.

PRODUCT FEATURES OF HOLLOW PADDLE DRYER

The stable operation of the hollow paddle dryer is another outstanding feature. The special compression-expansion stirring effect of the wedge-shaped blades ensures full contact between the material particles and the heat transfer surface. This creates a stable environment that maintains consistent temperature, humidity and mixing gradients across the material, ensuring reliable, efficient processing.

APPLICATION SCOPE OF HOLLOW SLUDGE PADDLE DRYER

Paddle dryer equipment has been successfully used in food, chemical, petrochemical, dye, industrial sludge and other fields slurry drying treatment process. The characteristics of heat transfer, cooling and stirring enable the following unit operations: combustion (low temperature), cooling, drying (solvent recovery) heating (melting), reaction and sterilization. The stirring paddle is also a heat transfer surface, which increases the heat transfer area per unit effective volume and shortenes the processing time. The heat transfer surface of wedge blade has the function of self-cleaning. Compression-expansion mixing function makes the material mix evenly. The material moves along the axial direction into a "piston flow", in the axial interval, the material temperature, humidity, mixing degree gradient is very small. Using heat conduction oil as heat medium paddle dryer can complete low temperature combustion work. For example, calcium sulfate dihydrate (Ca2SO4·2H2O) is burned and converted into calcium sulfate hemihydrate (Ca2SO4·1/22H2O). Sodium bicarbonate (NaHCO3) is converted into soda ash (Na2HCO3) by calcination. Through the cooling medium, such as water, cooling brine can be used for cooling. For example, the blade type soda cooling machine used in soda industry replaces the old air cooling soda cooling machine, which saves energy and exhaust gas treatment equipment and reduces operating costs. The main function of drying equipment, does not use hot air, so that solvent recovery, energy consumption, environmental control in an ideal state of easy handling. It is especially suitable for heat sensitive materials that need solvent recovery and are flammable and easy to oxidize. It has been widely used in fine chemical, petrochemical and dye industries. The uniformity of temperature, humidity, and mixing in the axial range enables the equipment to be used for heating or melting, or for some solid material reaction. It has been successfully used in compound fertilizer and modified starch industry. Paddle dryers can be used to sterilize food and flour. The large heating area in the unit effective volume quickly heats the material to the sterilization temperature, avoiding the change of material quality caused by long time heating.

description2