Project Introduction

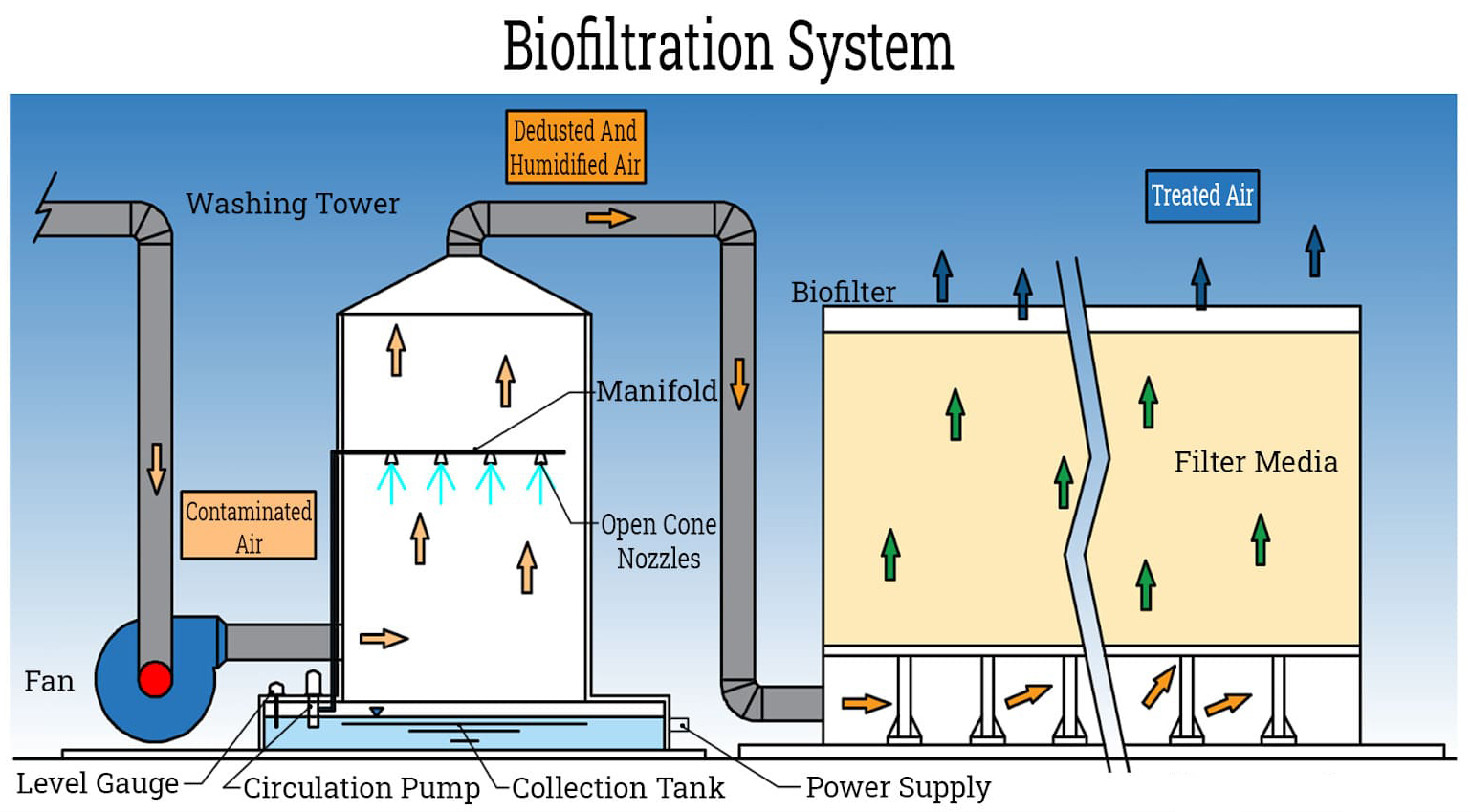

The inert artificial biological filler with porous, large specific surface area, easy biological attachment and easy degradation and decay is used as the fixed bottom layer. By uniformly spraying the circulating liquid containing nutrients and microorganisms, the biofilm is formed on the surface of the filler, and the volatile organic compounds and malodorous substances in the exhaust gas are decomposed and even mineralized by the metabolic activities of microorganisms. Metabolites are regularly excreted with the circulating fluid.

Launch of the latest innovative exhaust gas treatment solutions

In order to solve the problem of odor emissions and organic waste gas, we have launched a revolutionary deodorization solution to ensure high efficiency, low operating costs and zero secondary pollution. This cutting-edge technology is designed to effectively address any kind of malodorous gases, ensuring excellent deodorization and promoting a circular economy.

One of the outstanding features of this new exhaust treatment solution is its ability to not only reduce odors but also generate revenue through reduced emissions. The solution uses less energy, produces less hazardous waste and has a long service life, helping to not only reduce carbon emissions but also help achieve carbon neutrality.

In addition to the environmental benefits, this deodorizing system is durable and has a beautiful and durable design that reflects its high-quality construction. Incorporating such advanced technologies into exhaust treatment emphasizes a commitment to sustainable practices and environmental stewardship.

The technology works by effectively neutralizing and eliminating odors and organic waste gases, solving a major problem for industries and communities. With high deodorization efficiency and low operating costs, this solution provides a sustainable and cost-effective method of exhaust gas treatment. Moreover, its zero secondary pollution ensures that the surrounding environment will not be damaged during the deodorization process.

This waste gas treatment solution is in line with the principles of the circular economy as it not only solves environmental problems but also provides businesses with the opportunity to reduce costs and generate revenue through emission reductions. By integrating this innovative technology into their operations, companies can contribute to a cleaner, more sustainable future while reaping financial benefits.

The launch of this advanced deodorization solution marks an important step towards achieving environmental sustainability and promoting circular economy practices. By investing in technologies that are efficient, have low environmental impact and are cost-effective, industries can play a key role in reducing their carbon footprint and building a more sustainable future for all.

Recent advances in waste gas treatment represent significant progress in addressing environmental challenges while also providing opportunities for businesses to thrive in a sustainable, environmentally friendly manner. This innovative solution is bound to have a positive impact in the fields of waste gas treatment and environmental protection with its promise of high efficiency, low operating costs and zero secondary pollution.

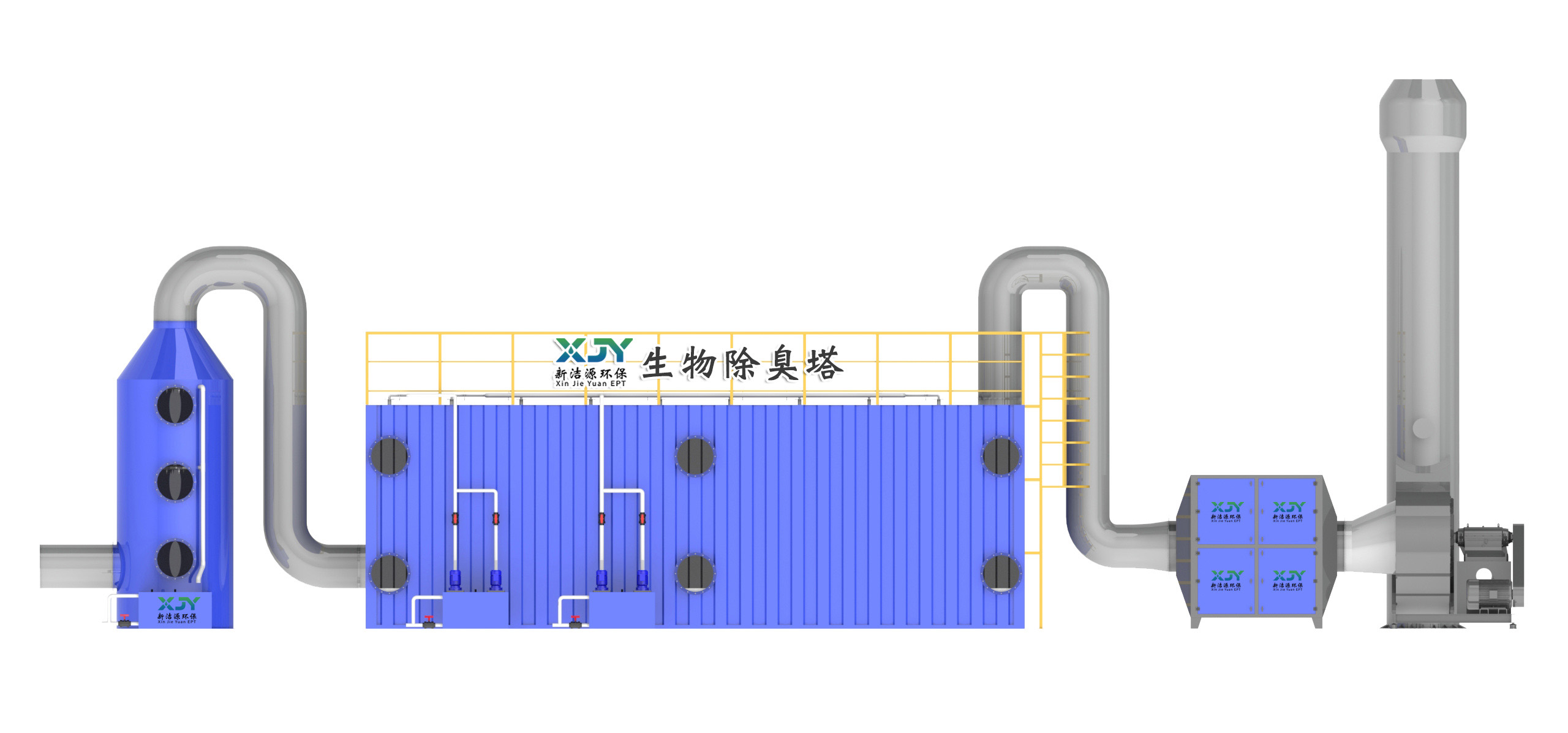

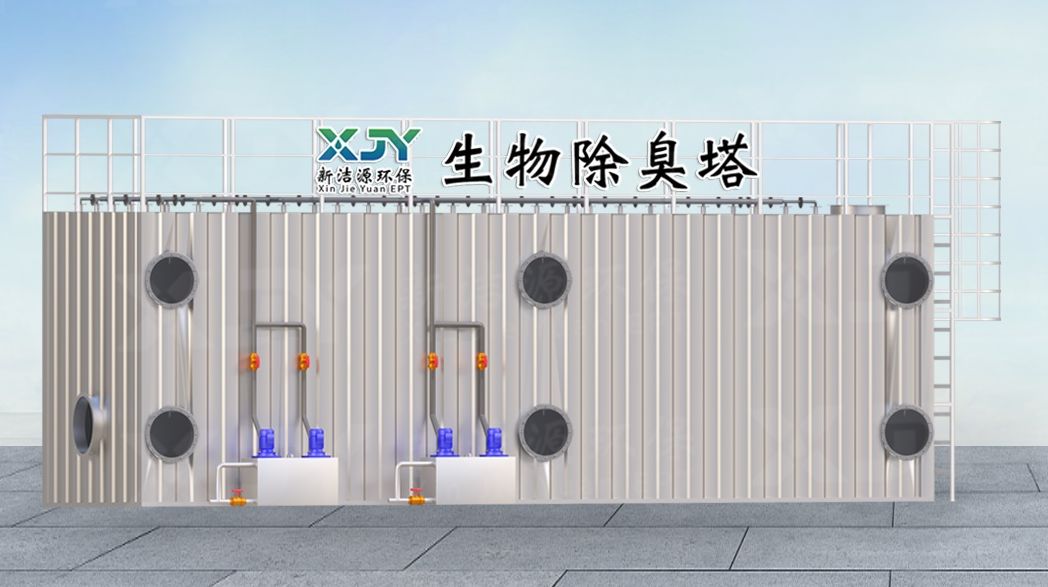

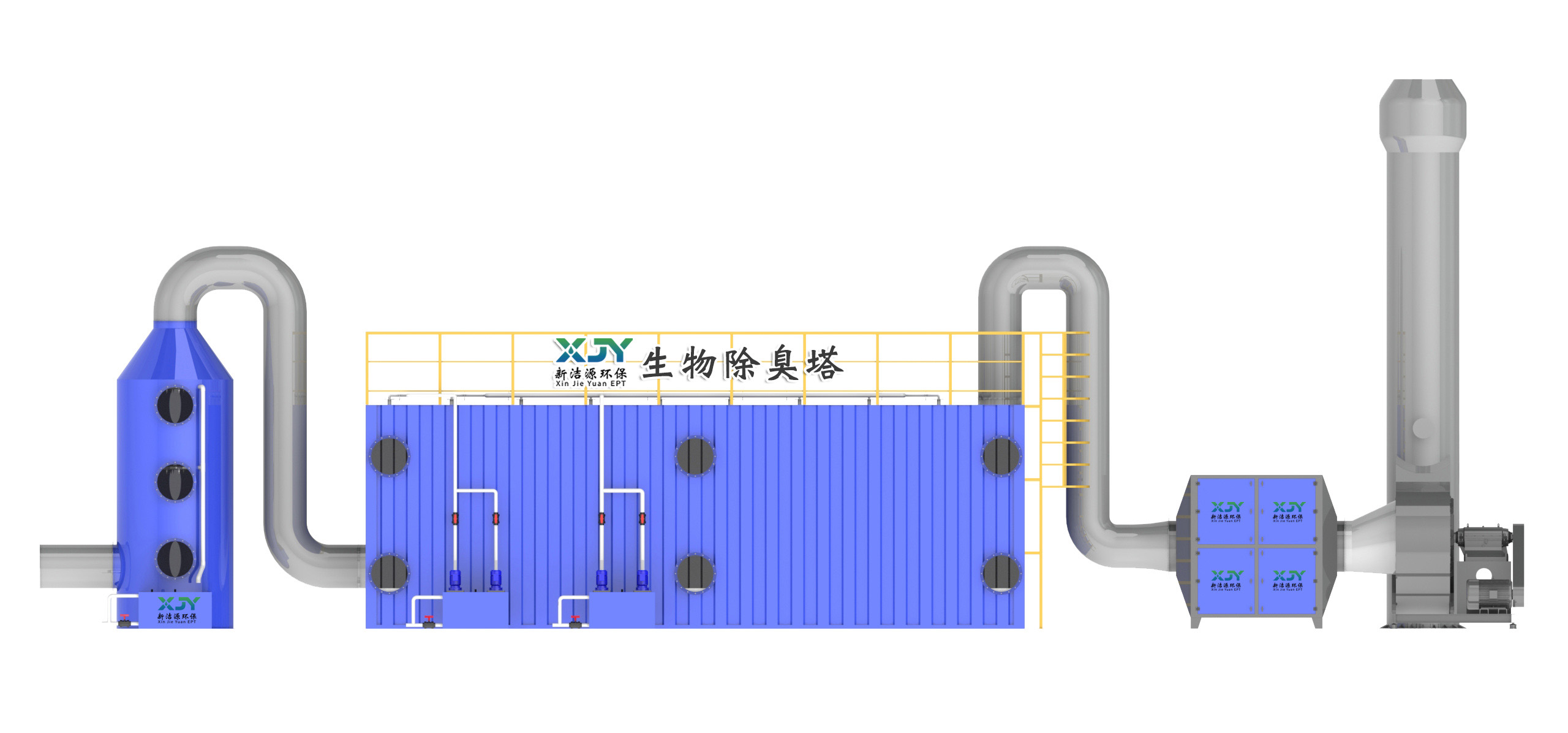

Biological deodorization equipment is mainly composed of odor collection system, biotrickling filter systems, control and monitoring system, and gas emission system. The odor collection system consists of air collecting hood, air duct and fan. So the main equipments and componts are spray tower, bioflter biological deodorization tank tower,Activated carbon adsorption tank box.

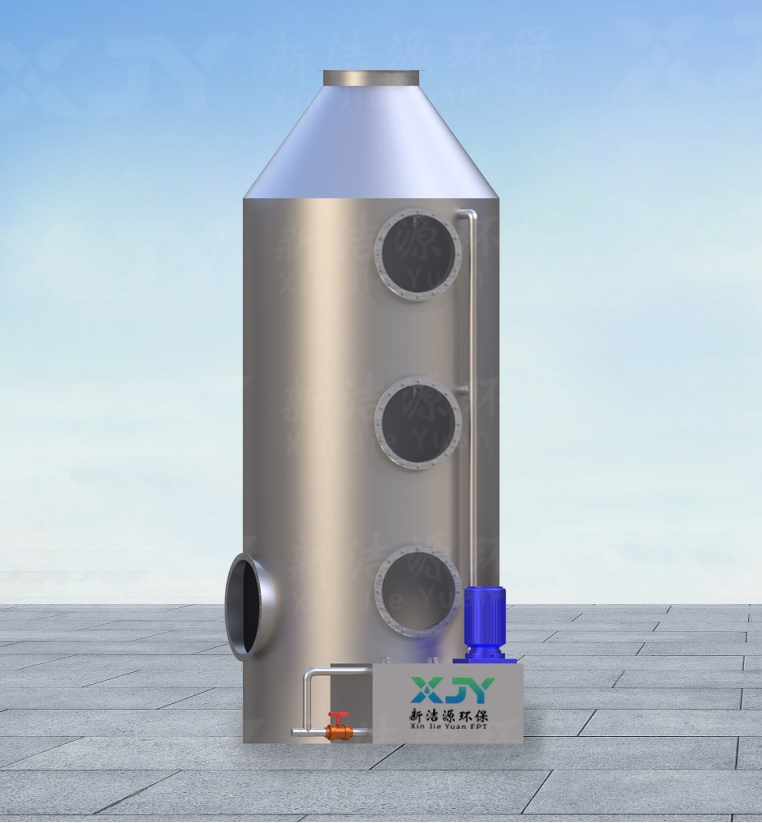

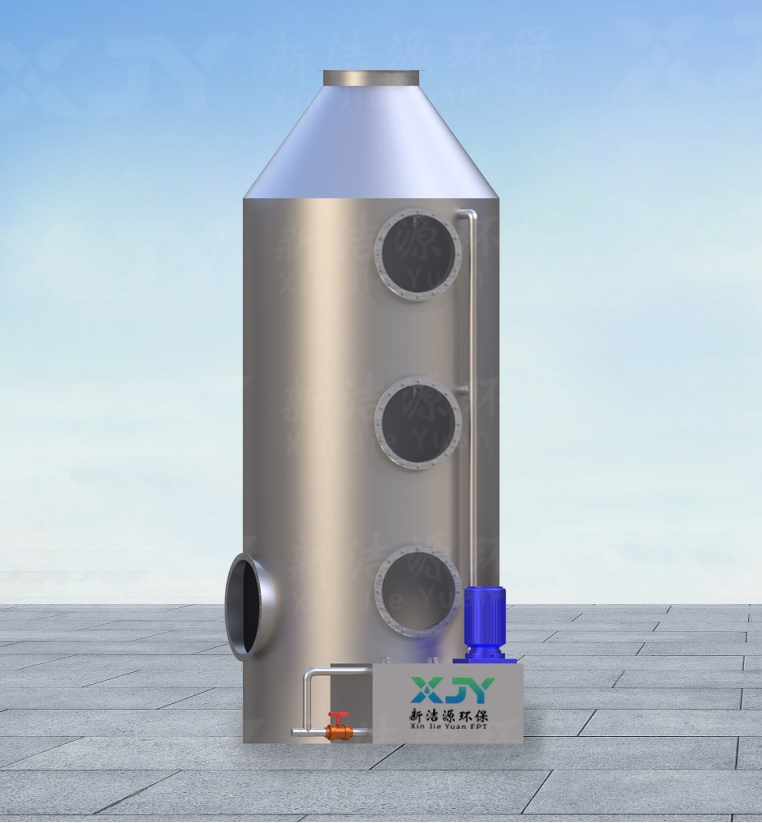

Spray Tower

Also known as spray column or wet scrubber, designed for biological waste gas treatment systems and biological wastewater odor control equipment. This state-of-the-art equipment is the ultimate solution for classification, dust and smoke removal in odor management systems.

Spray towers are equipped with a range of advanced features, making them an essential component of any biological waste odor treatment system. Its high dust collection and desulfurization efficiency ensures that the air is thoroughly purified, reaching an impressive 85% when using alkaline wash water. This makes it ideal for effectively removing odors and harmful substances from exhaust gases.

The device's compact design means it takes up minimal space and is easy to install, making it a convenient and practical addition to any exhaust treatment system. The spray tower has low water consumption and power consumption indicators, which not only has high efficiency, but also has low operating costs. Additionally, its corrosion resistance and long service life ensure reliability and durability even in the most demanding environments.

In addition, the equipment is designed to operate reliably and be easy to maintain, reducing expensive and time-consuming maintenance. With these features, spray towers are a reliable and efficient choice for any biological waste gas treatment system and biological wastewater odor control equipment.

Overall, the spray tower provides a complete and effective solution for classification, dust removal and smoke removal in odor treatment systems. Its high efficiency, compact design and low operating costs make it ideal for any facility looking to enhance biological waste gas treatment capabilities. With a spray tower, you can be confident that your odor management system is delivering optimal results in a cost-effective manner.

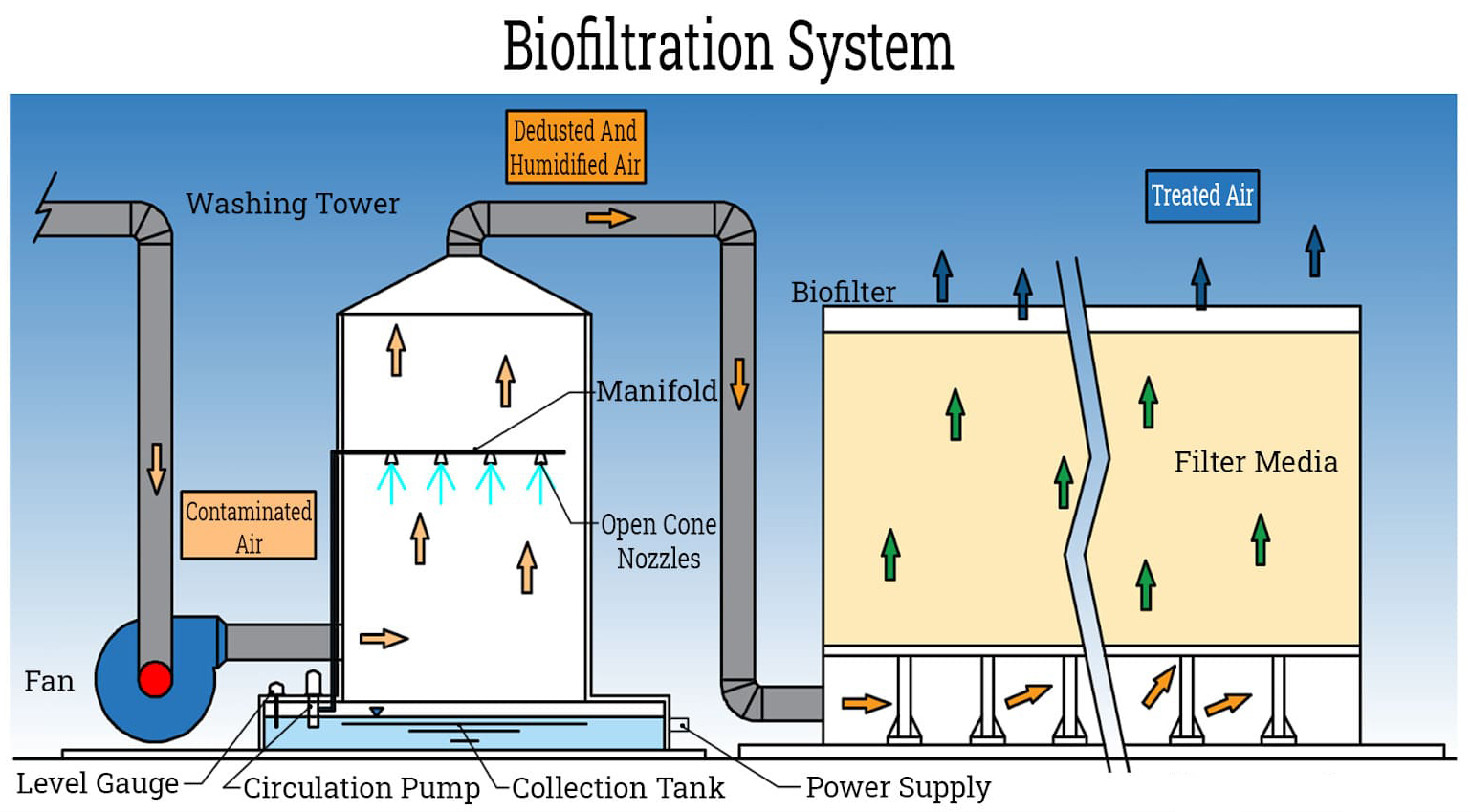

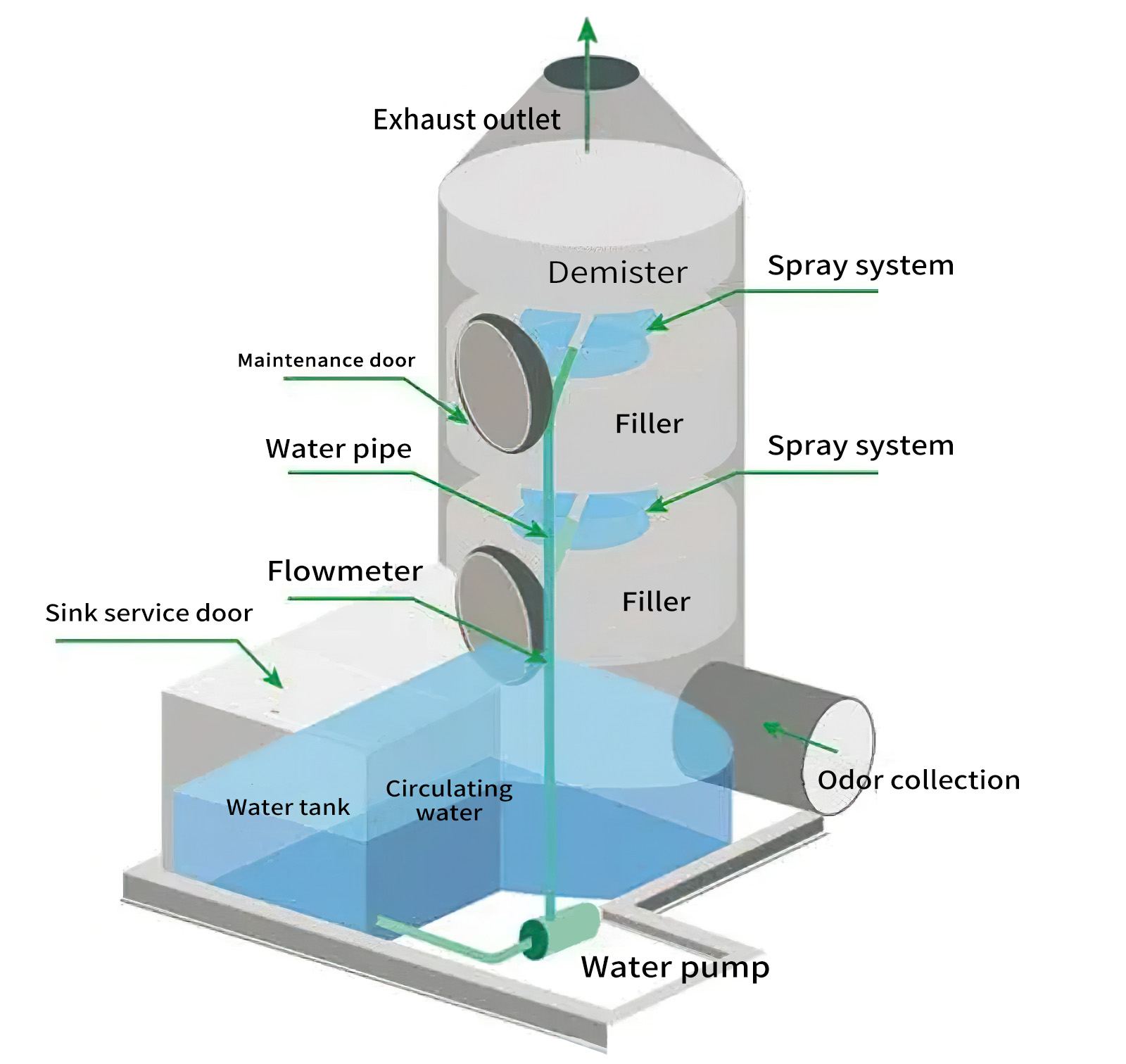

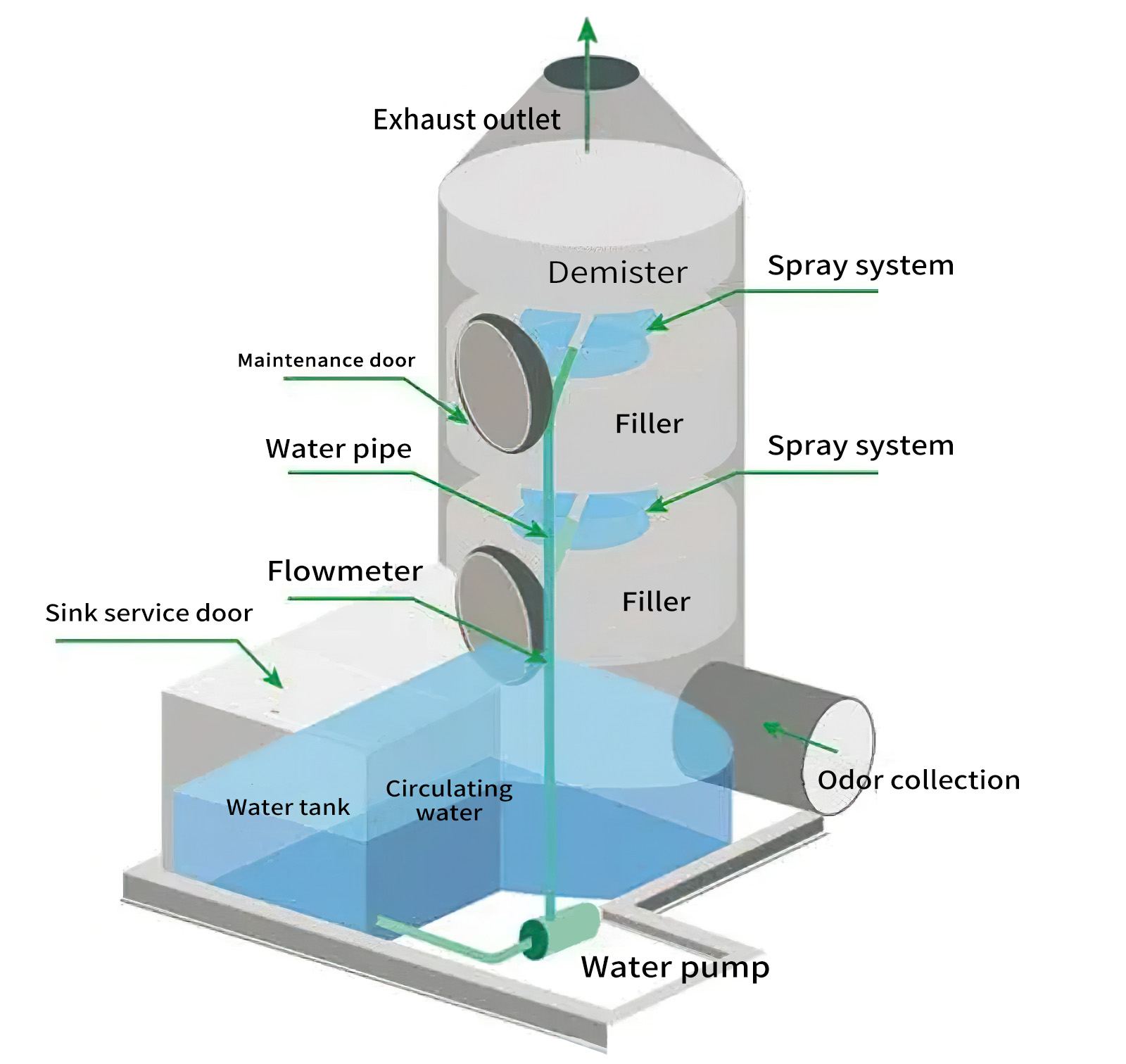

The function and working principle of spray tower in biological deodorization system are crucial to the efficient purification of odorous gases. In the deodorization process of gas purification equipment, various instruments and equipment are used, among which the spray tower plays an important role in effectively purifying the air.

A spray tower, also known as a spray column or wet scrubber, is a gas purification equipment used in the deodorization process. It is designed to remove dust, cool, humidify and neutralize acidic or alkaline malodorous gases. This equipment is a key component for biological wastewater odor control in biological waste gas treatment systems.

The odorous gas undergoes a preliminary treatment process through chemical scrubbers to remove dust and cool and humidify the gas. If the exhaust gas is acidic, an alkali spray process is used to neutralize the acidity. On the other hand, if the exhaust gas is alkaline, it is absorbed and neutralized with sulfuric acid solution as a pretreatment step.

Subsequently, the odorous gas enters the biological deodorization tower. The tower is equipped with an inert artificial biopacking material that has a large specific surface area and porosity, making it ideal for bioadhesion. The circulating liquid containing nutrients and microorganisms is evenly sprayed onto the filler to form a biofilm on its surface. This kind of biofilm uses the metabolic activity of microorganisms to decompose and mineralize volatile organic compounds and odorous substances in the exhaust gas, effectively purifying the exhaust gas. The metabolites are then periodically excreted with the circulating fluid.

In summary, the spray tower is an important part of biological deodorization in biological waste gas treatment systems. Its efficient working principle ensures the effective purification of odorous gases, making it an important part of biological sewage odor control equipment. Its use in gas purification equipment is crucial to maintaining clean air and reducing environmental pollution.

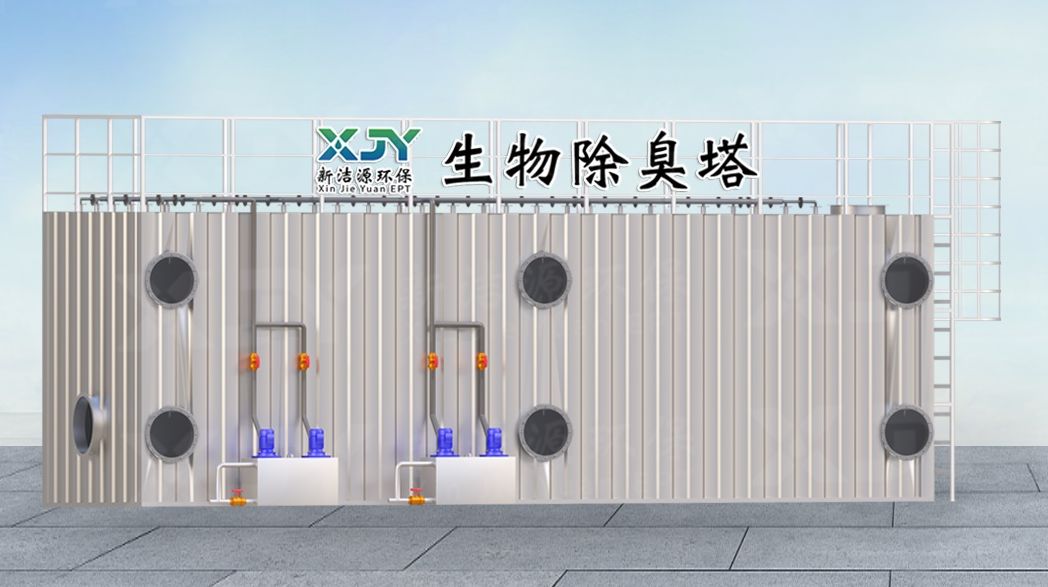

Bioflter Biological Deodorization Tank Tower

Biotrickling filter systems, also known as Biotowers, Biotricklers, Bioscrubbing Systems, Bioscrubbers, and Biological Oxidation Systems. Biotrickling Filters use a synthetic media to support the growth of natural occurring micro-organisms to convert H2S into a dilute acid solution, part of which is discharged via a continuous water make-up or overflow. The Biotrickling Filter uses continues recirculation of a nutrient-rich solution to promote the biological growth.

Introduction to the structure and principle of biological deodorization tower

Biological deodorization is currently the most widely used method in the field of sewage and VOCs deodorization. The biological deodorization tower is an important part of the biological deodorization system. This equipment plays a vital role in treating biological waste gas and controlling sewage odor, biotrickling filter systems is an indispensable part of the biological filtration process system.

Biological deodorization principle

The principle of biological deodorization is to use microorganisms to convert odorous substances into harmless compounds. During the growth process, microorganisms can convert external substances into metabolites such as carbon dioxide and water, or convert them into harmless cellular substances. This biochemical process converts pollutants into non-polluting substances. However, gas phase substances are usually difficult to undergo biochemical reactions due to their low concentration. Therefore, the biological purification process of odor needs to be completed through the filtration process of the biological deodorization tower.

Biological deodorization tower structure

The biological deodorization tower is designed to effectively remove odorous substances in exhaust gas. The exhaust gas enters from the bottom of the tower and is absorbed by the microorganisms in the packing section. These odorous substances are then transferred to microorganisms and used as energy and nutrients during microbial metabolism. As a result, odorous compounds are broken down and converted into harmless compounds. The treated gas is discharged from the biological deodorization tower to complete the biological deodorization process.

In addition, the waste gas is pre-treated before entering the biological deodorization tower. Pretreatment includes the removal of particulate matter from the front-stage washing bed and the adjustment of temperature and humidity. The gas is then pumped through a centrifugal fan into a biotower filled with bioactive media. The filler contains a certain amount of moisture that allows various microorganisms to grow on its inner surface. Through gas-liquid and liquid-solid mass transfer, odorous compounds are degraded by microorganisms in the tower.

The importance of biological deodorization tower equipment

Biological deodorization tower equipment is crucial to effectively remove odorous substances in exhaust gas. It provides a favorable environment for the growth of microorganisms and promotes the biochemical reactions needed to break down odors. In addition, it plays a vital role in the biological filtration process system to ensure efficient treatment of biological waste gas and control of sewage odor.

To sum up, the biological deodorization tower is an important part of the biological deodorization system. Its structure and principle can effectively remove odorous substances in waste gas, making it a key equipment in the fields of biological waste gas treatment and sewage odor control. As the most widely used method in the industry, biological deodorization processes are indispensable for ensuring environmental protection and public health.

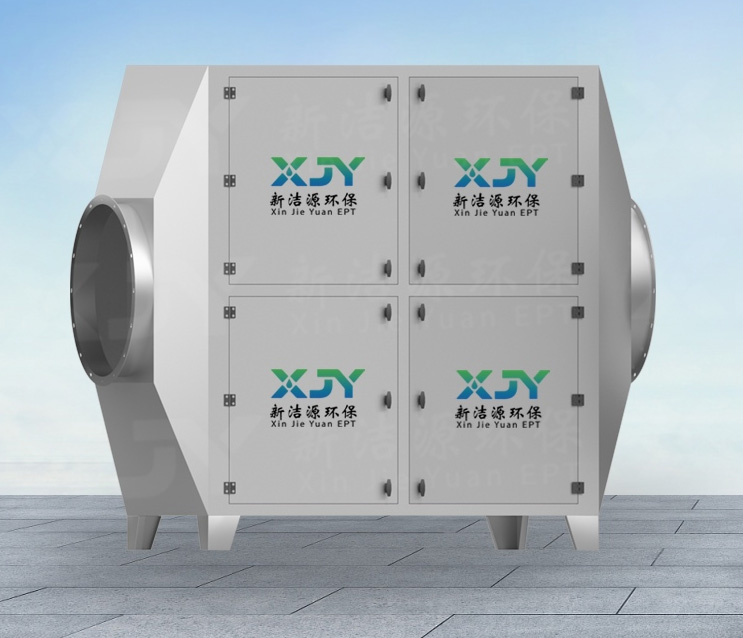

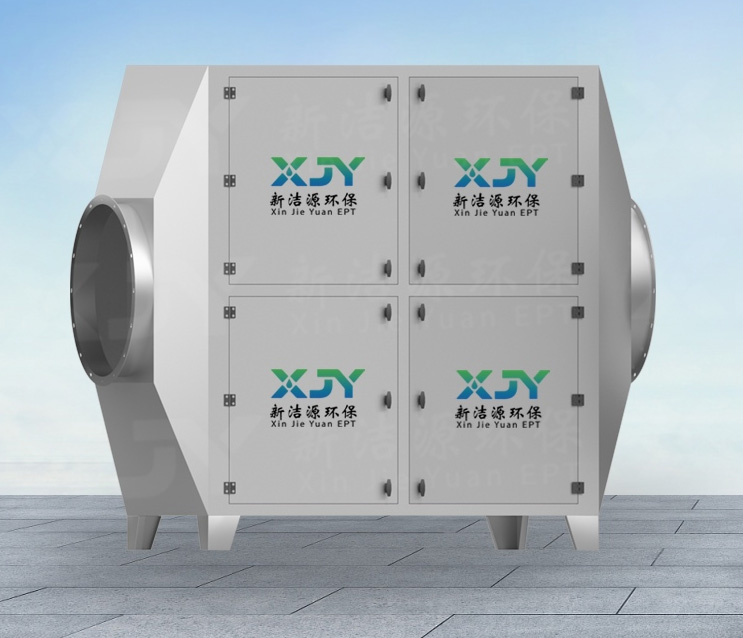

Activated Carbon Adsorption Tank Box

Activated carbon adsorption box can also be called activated carbon adsorption tower, activated carbon adsorption device, activated carbon waste gas treatment equipment, activated carbon filter, activated carbon equipment.

Activated carbon adsorption box is an important and widely used equipment in environmental protection, water treatment, chemical industry, medicine and other industries. Its function is to use the adsorption properties of activated carbon materials to effectively remove pollutants in the air. This is achieved by the polluted air passing through the activated carbon layer in the activated carbon adsorption box, causing a physical or chemical reaction between the pollutants and the surface of the activated carbon to form an adsorption process.

The activated carbon adsorption box is an exhaust gas adsorption device specially used to adsorb harmful gases to improve air quality. It is known for its ability to effectively remove harmful gases such as formaldehyde, benzene, sulfur dioxide, carbon monoxide, nitrogen oxides and other pollutants commonly found in industrial waste gases.

The high efficiency of the activated carbon adsorption box is mainly due to the unique structure of activated carbon. Activated carbon is composed of porous carbon atoms and has high adsorption performance. These pores enable activated carbon to adsorb large amounts of pollutants and effectively remove harmful substances from the air.

The adsorption process of the activated carbon adsorption box is to use the adsorption capacity of the activated carbon surface to bring the exhaust gas into contact with the large surface area porous activated carbon adsorbent. When pollutants in the exhaust gas come into contact with the surface of activated carbon, they are adsorbed, thereby separating them from the gas mixture and purifying the air. The adsorption capacity of activated carbon mainly depends on the pore structure of its surface and the specific surface area of activated carbon, which together determine the overall adsorption effect.

During the adsorption process, the exhaust gas enters the activated carbon adsorption box from the air inlet, and first passes through the filter to remove particulate matter. Then it enters the adsorption section, where the pollutants in the exhaust gas are attracted by the adsorption force on the surface of the activated carbon adsorbent and remain on the surface of the activated carbon.

The technical principles and functions of the activated carbon adsorption box make it an important part of waste gas treatment equipment and sewage odor control systems. It plays a vital role in ensuring the effective removal of harmful gases and pollutants in industrial waste gas, thereby preventing environmental pollution and improving air quality.

To sum up, the activated carbon adsorption box is an efficient and effective way to remove air pollutants. Its use in various industries and applications makes it an indispensable multi-functional device in environmental protection, waste gas treatment, and odorous gas treatment systems. It can use the adsorption capacity of activated carbon to purify the air and remove harmful gases, making it an important tool to protect the environment and public health.