Project Introduction

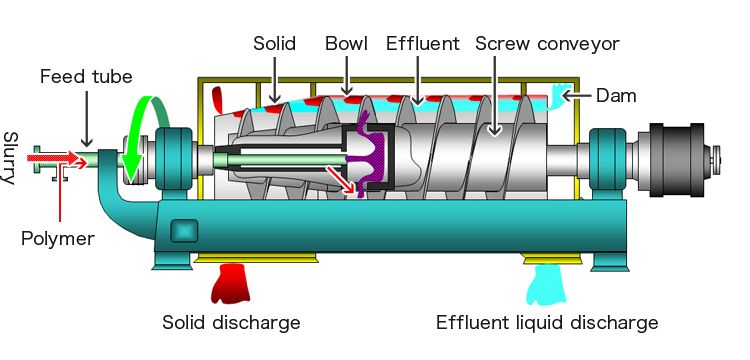

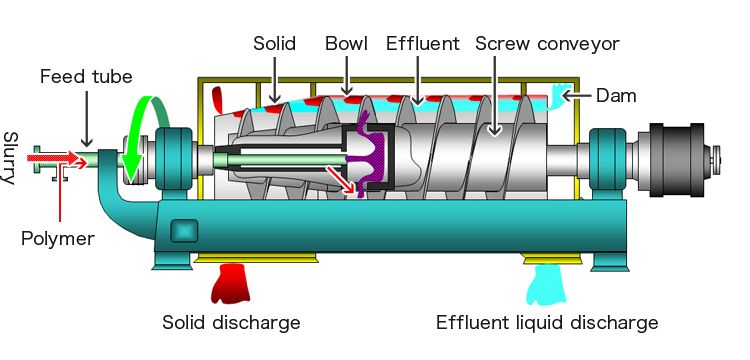

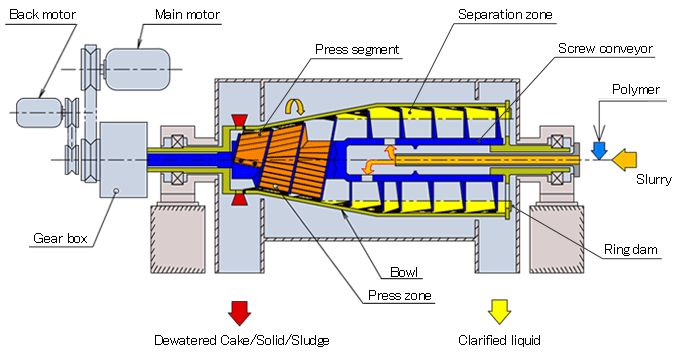

Structure of screw decanter centrifuge equipment:

Horizontal screw decanter centrifuge structure is horizontal, is a continuous operation, the use of screw conveyor discharge equipment, belongs to the solid - bowl scroll discharge centrifuge, referred to as the decanter centrifuge.

The structure of the spiral decanter centrifuge equipment is crucial to its efficient and effective operation. This article will discuss the main components and their functions to provide a comprehensive understanding of the device.

Organization Composition

Horizontal screw centrifuge is mainly composed of drum, screw, differential system, liquid level baffle, driving system and control system, etc. Horizontal screw centrifuge is to use the density difference between solid and liquid two phases, under the action of centrifugal force, accelerate the settlement speed of solid phase particles to achieve solid-liquid separation, the specific separation process is sludge and flocculation liquid is sent into the mixing chamber of drum through the inlet pipeline. Mixed flocculation is carried out here (if the sludge pump is dosed before or the pipeline is dosed after the pump, the flocculation reaction has been advanced).

Due to the high speed rotation and friction resistance of the rotor (screw and drum), the sludge is accelerated inside the rotor and forms a cylindrical liquid ring layer (liquid ring zone). Under the action of centrifugal force, the solid particles with large proportion settle to the inner wall of the drum to form a mud layer (solid ring layer), and then the relative speed difference between the screw and drum is used to push the solid phase to the cone end of the drum. After pushing out the liquid level (shore area or dry area), the mud and slag can be dehydrated and dried, and discharged to the slag outlet. The filtrate is discharged from the large end of the drum through the reflux tube to achieve solid and liquid separation.

Core Structure

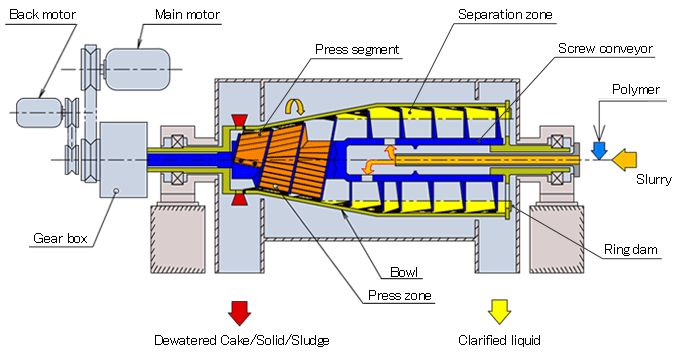

Horizontal spiral settling centrifuge (referred to as decanter centrifuge) is the key equipment to achieve solid-liquid separation. The differential speed between the drum speed and the screw propeller determines the separation effect and efficiency of materials. The traditional decanter centrifuge (including two-phase and three-phase) adopts the principle of mechanical transmission.

Main structure:

1) The drum is a key component of the centrifuge. It is designed to withstand high-speed rotation and the centrifugal pressure exerted by materials and other attachments. The drum consists of four parts: cylinder, cone, large end cover, and small end cover, all of which are connected by flanges. There is a radial slag discharge hole near the connection between the cone and the small end flange, and an overflow hole on the large end cover. The depth of the liquid pool is adjusted by the eccentric overflow plate. The drum material is nickel-plated and phosphorus-plated No. 35 steel to ensure strength, corrosion resistance and weldability.

2) The screw conveyor plays a vital role in continuously transporting sediment to the slag discharge port and discharged out of the machine. According to the solid-liquid ratio of the materials to be processed, the ratio of the filling channel and the slag discharge channel can be adjusted. An accelerating rotation device is welded at the spiral body feed to prevent the separation effect from being reduced due to rotation lag. In addition, the small end of the spiral body is welded with a reverse spiral to prevent sediment accumulation. The screw conveyor is made of the same material as the roller, made of nickel-plated and phosphorus-plated No. 35 steel.

3) The hydraulic motor is responsible for achieving the differential speed between the screw and the drum. The oil supply volume of the hydraulic motor can be automatically adjusted through the oil delivery joint.

4) The main bearing is hydraulically driven and is designed with a hydraulic station. Since the drum speed is usually around 3000r/min, thin oil lubrication is used to ensure optimal performance. Lubricating oil is supplied in a circulating manner to provide lubrication and cooling to the bearings.

5) The machine base adopts I-beam welded structure and uses four rubber shear shock absorbers for shock absorption. This design helps minimize vibration and provides stability during operation.

It is worth noting that these components are critical to the normal operation of the spiral decanter centrifuge equipment. With the right structure and components, this equipment can effectively separate solids from liquids in a variety of industrial processes. The use of high-quality materials and precision engineering ensures the equipment's durability and reliability, making it a vital asset in many industries.

Working principle of screw decanter centrifuge machine

The drum and the screw rotate at a certain differential speed in the same direction at high speed. The material is continuously introduced into the inner barrel of the conveying screw from the feeding pipe, and then enters the drum after acceleration. Under the action of centrifugal force field, heavy solid precipitates on the wall of the drum to form a sediment layer. The conveying screw continuously pushes the deposited solid phase to the cone end of the drum and discharges it out of the machine through the slag discharge port. The lighter liquid phase forms the inner liquid ring, which continuously spills over the drum from the overflow port at the large end of the drum and is discharged out of the machine through the drain port.

The equipment can continuously feed, separate, wash and discharge materials at full speed. It has the characteristics of compact structure, continuous operation, stable operation, strong adaptability, large production capacity and convenient maintenance. It is suitable for separating suspensions containing solid phase with particle size greater than 0.005mm and concentration range of 2-40%.

The main function of the horizontal spiral centrifuge is to separate the solid from the liquid (that is, the separation of two phases). In the process of clarification, the suspended solid is affected by the centrifugal force and the opposite buoyancy and flow resistance, and the clarification speed is the result of the comprehensive action of the above forces.

The flow resistance depends on the size and shape of the particles and the viscosity of the liquid. The friction between the liquid and the settled solid, the swirling of the spiral rotation and the agitation of the rotating cylinder together produce a comprehensive dynamic effect, which has a strong effect on the semi-static settlement in the centrifuge. The separation characteristic of decanter centrifuge is that it is a continuous separation process, and the solid content of the separated suspension is high.

Affecting Factors of the decanter centrifuge separation effect

To understand the separation effect of decanter centrifuge, first need to know its principle of action, that can be effectively controlled in use.

The speed of the decanter centrifuge drum

The adjustment of drum speed is usually realized by frequency conversion motor or hydraulic motor. The increase of drum speed will improve the separation effect. The greater the speed is, the greater the centrifugal force is, which is helpful to improve the solid content of mud cake.

Increasing the speed difference between the screw and the drum will increase the treatment capacity, but too fast speed will destroy the sludge flocs, so reduce the dehydration effect. The higher the rotational speed, the higher the solid dryness is not necessarily.

In addition, higher speed will cause machine vibration, the wear of the machine increases, power consumption, vibration and level will increase accordingly, reduce the service life of the equipment.

Therefore, the speed should be reasonably selected to meet the separation requirements.

Feed flow rate (handling capacity)

The feed flow affects the retention time of the material in the equipment, and then affects the separation effect.

The smaller processing capacity makes the axial flow velocity of the material liquid smaller, and the residence time in the drum is longer, and the separation effect is better; On the contrary, excessive feed flow will reduce the separation effect.

In addition, the feed flow rate is also related to the solid content of the material liquid and the slag discharge capacity of the centrifuge screw. Excessive feed flow rate may cause the drum to block the material and affect the separation effect.

Therefore, the feed flow should be reasonably selected to match the solid content and separation requirements of the material liquid.

Overflow plate diameter

The large end of the drum is provided with an overflow plate, which can control the liquid depth of the liquid ring layer by adjusting the diameter of the overflow plate.

The small diameter overflow plate can increase the depth of the liquid ring layer and make the separation liquid clear. On the contrary, when the overflow plate diameter is increased, the separation liquid obtained has low clarity and poor separation effect.

Differential speed of drum and screw

Differential velocity directly affects the slag discharge capacity, mud biscuit degree and filtrate quality, which is one of the important parameters that need to be adjusted according to the operation situation in the operation of decanter centrifuge.

The smaller differential speed has better separation effect, but it is easy to produce blockage because the solid particles stay in the drum for a long time. The larger difference speed, because of the screw to the liquid layer of the disturbance, so that the separation effect is poor, but has a better slag discharge capacity.

Therefore, according to the material properties, processing capacity, processing requirements and centrifuge structural parameters to determine the size of the differential speed, small solid content matching small differential speed, large solid content matching large differential speed.

Aspect ratio

The larger the aspect ratio of horizontal screw decanter centrifuge is, the stronger the processing capacity is and the better the separation effect is.

Characteristics of sewage liquid

The size of the solid particles in the material is different, the centrifugal force is different, and the separation effect is different.

The larger the particle, the easier the separation; Too small particles, easy to mix in the separation solution, with the separation solution overflow.

In addition, the difference between the specific gravity of solid and liquid two phases and the viscosity of suspension also affect the separation effect. The greater the difference between the specific gravity of solid and liquid two phases is, the easier it is to separate, and the smaller the viscosity of suspension is, the easier it is to separate.

...

Of course, in addition to the above factors, there are many factors that affect the separation effect of the decanter centrifuge, such as the thickness of the liquid ring layer, such as the process factors, and these factors affect each other, the treatment effect is the result of the comprehensive action of the above factors.

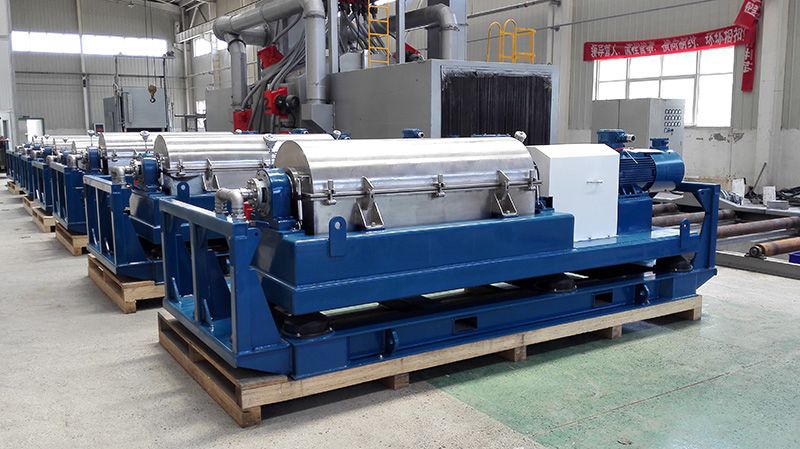

Advantages of products

Horizontal screw centrifugal dehydrator has the following advantages:

Decanter centrifuge, also known as decanter centrifuge, is widely used in various industries to separate solids and liquids. These machines are available in different types such as vortex decanter centrifuge, drum decanter centrifuge and solid drum decanter centrifuge. Flottweg Decanter Centrifuge is one of the best-known brands in the industry, renowned for its high-quality decanter centrifuges.

There are several advantages to using horizontal screw centrifugal dehydrators for industrial separation processes. One of the main advantages is the large processing power provided by these machines. Due to its advanced technology, the decanter centrifuge can handle large quantities of materials, making it suitable for a wide range of processing needs. This makes them very efficient and cost-effective for industries that handle large volumes of liquid-solid mixtures.

Additionally, these machines are also known for their energy-saving and environmentally friendly features. The decanter centrifuge has low noise and vibration levels during operation and consumes minimal energy. Moreover, the machine will not produce secondary pollution in the process of processing sludge and other waste, meeting the requirements of energy conservation and environmental protection. This makes them a top choice for industries aiming to reduce their environmental footprint.

In addition to their processing capabilities and environmental benefits, horizontal spiral centrifugal dehydrators are also praised for their user-friendly features. These machines are simple to operate and require minimal training to operate. This not only increases productivity but also reduces the possibility of errors during operation.

Last but not least, maintenance is often an issue with industrial machinery. However, decanters are known for their ease of maintenance and long service life. This reduces downtime and overall maintenance costs, making it a reliable choice for industrial processes.

In summary, horizontal spiral centrifugal dehydrators offer a range of advantages that make them a popular choice for industries that require solid-liquid separation. These machines offer high throughput, energy efficiency, simple operation and maintenance, making them an ideal investment for businesses looking to increase efficiency and reduce environmental impact.