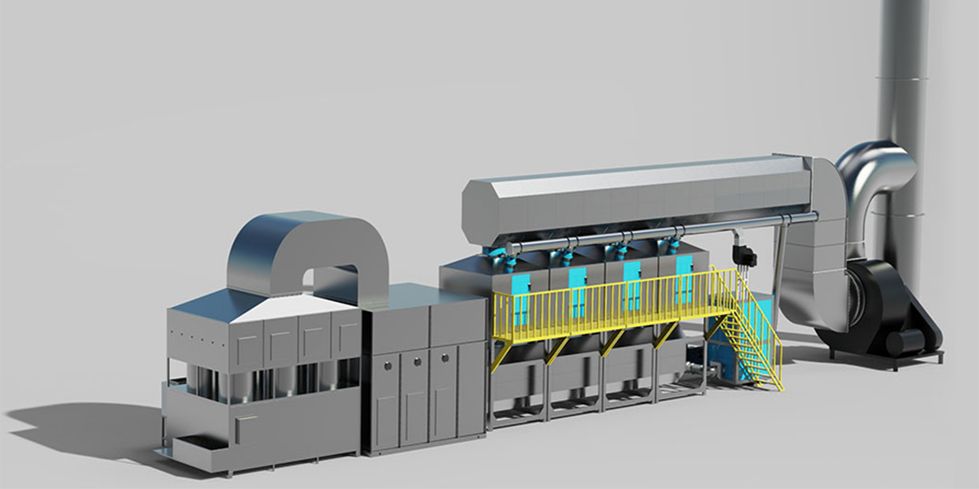

Activated Carbon Adsorption & Catalytic Combustion Equipment VOCs Exhaust Waste Gas Treatment

Project Introduction

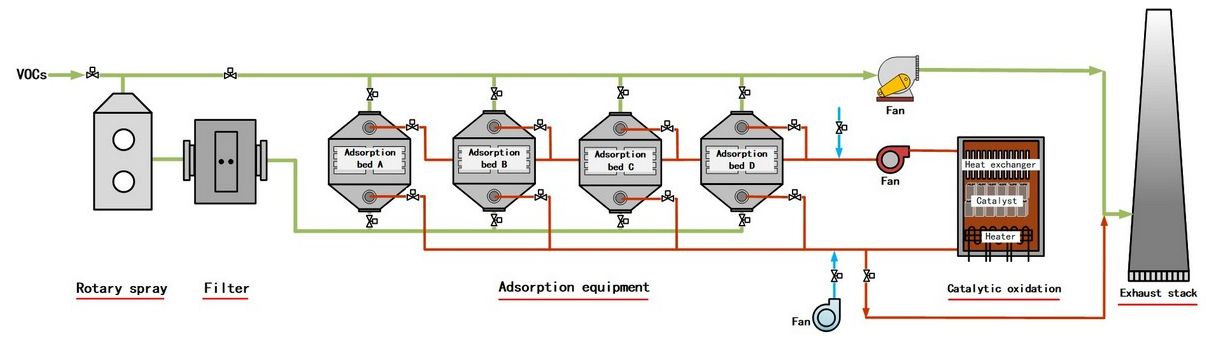

Activated carbon adsorption and desorption and catalytic combustion systems (RCO) are becoming more and more popular in the treatment of VOCs exhaust gas. The combination of activated carbon adsorption and catalytic combustion equipment provides a comprehensive solution for efficient and environmentally friendly treatment of organic waste gas.

The PLC control system is another significant feature of the RCO system. It can interlock control the activated carbon adsorption bed and catalytic oxidation equipment, as well as electric heating power, flue gas outlet damper control, fan, furnace temperature, pressure, and air direction switching valve Signal interlock control, etc. This centralized control and monitoring system enables the RCO system to operate efficiently and effectively, ensuring that all faults can be analyzed and dealt with in a timely manner.

In summary, the performance and characteristics of activated carbon adsorption and desorption and the catalytic combustion system (RCO) make it an ideal choice for treating VOCs exhaust gases. RCO systems are highly efficient, low operating costs and environmentally friendly, providing a comprehensive and sustainable solution for businesses looking to reduce emissions and comply with regulatory requirements.

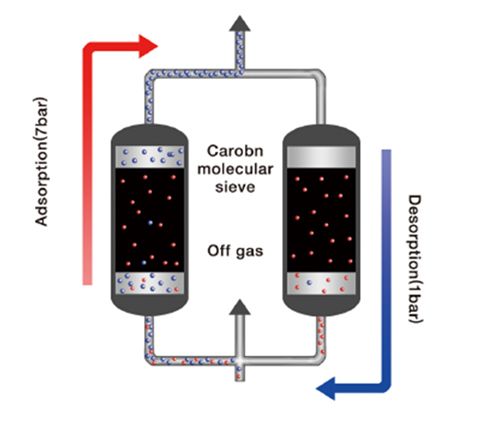

Adsorption and desorption of activated carbon

VOCs Catalytic Combustion Treatment Technology and Application

Applicaton

description2