1. Mutete firimu drying system process inoyerera

Sludge medium process: wet sludge inogamuchira bin + sludge delivery pombi + nhete firimu dryer + semi-dry sludge output equipment + linear dryer + chigadzirwa chinotonhorera.

Exhaust gasi medium process: evaporation steam (yakavhenganiswa steam) + tsvina gasi bhokisi + condenser + mhute eliminator + induced draft fan + deodorization mudziyo.

Dope riri mudhaka rekugamuchira bhini rinotumirwa zvakananga kune yakaonda firimu dryer nesludge screw pump yekuomesa kurapwa. Iyo sludge inlet yeyakaonda firimu dryer yakashongedzerwa nepneumatic banga regedhi vharafu, iyo yakavharika neiyo logic yekudzora paramita yepombi yekudyisa, feeding screw, kuchengetedza kuchengetedza kweyakaonda firimu dryer uye zvimwe midziyo nekuona zviridzwa.

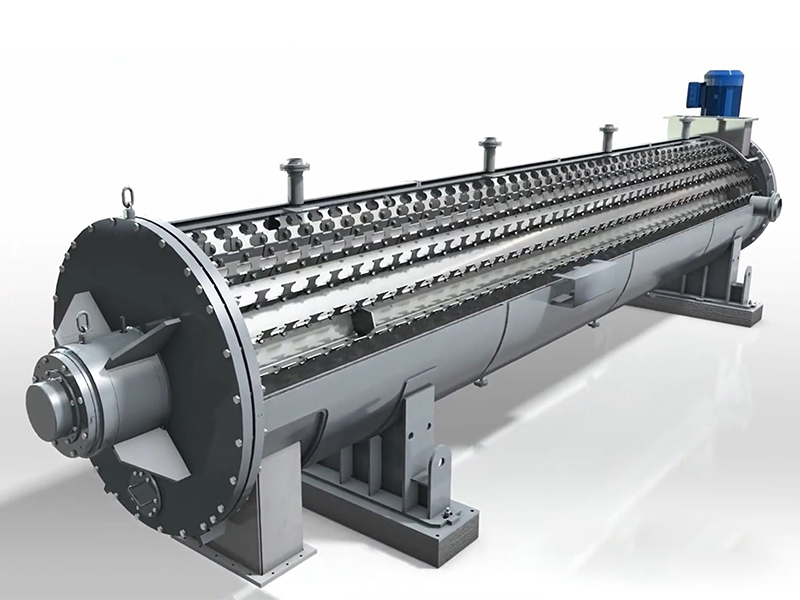

Iyo yakaonda firimu inoomesa muviri modhi, huremu hwemuchina mumwe chete i33 000 kg, mambure saizi yemidziyo ndeye Φ1 800 × 15 180, yakachinjika dhizaini uye kuisirwa, sludge inopinda mutete firimu dryer inogoverwa zvakaenzana pane inopisa. madziro emadziro emuomese ne rotor panguva yekutenderera, nepo paddle pa rotor ichidzokorora kusanganisa sludge pamadziro anopisa emadziro, Uye kumberi kwekubuda kwesludge, mvura iri musludge inoputika mukuita. . Iyo semi-yakaoma sludge particles mushure mekuomeswa kubva kune yakaonda layer inotakurwa ichiendeswa kune linear dryer kuburikidza nesludge conveyor (inogadziriswa zvinoenderana nekudiwa kwehunyoro hwechigadzirwa chedhaka), uye wozopinda mune inotonhorera inotonhorera. Chigadzirwa chematope chinotonhodzwa nemhepo inoyerera muinotonhorera uye mvura inotonhorera inoyerera mugoko uye shaft inotenderera. Hunyoro hwemukati hunodzikiswa kubva pa80% kusvika 35% (iyo hunyoro hwematope hwe35% ndiyo nzira yekudzora muganho wepamusoro wemudziyo mumwechete weiyo yakaomeswa firimu).

Iyo inotakura gasi inoburitswa kubva mutete firimu dryer ine yakawanda yemvura mhute, huruva uye imwe huwandu hwegasi rinoputika (kunyanya H2S uye NH3). Kana ikaburitswa zvakananga, inokonzeresa mwero wakati wekusvibiswa kune zvakatipoteredza. Naizvozvo, chirongwa ichi chinotarisa inotakura gasi yekuunganidza system uye condenser uye mhute inobvisa kuti ibvise guruva nemhute yemvura mumhepo yekuburitsa gasi, iyo yakatarisana negwara rekufamba kwedhaka muhumburumbira inotenderera. Iyo yekubuditsa gasi pombi inobuda pamusoro pesludge inopinda mucondenser, uye mvura inotonhodzwa kubva pamhepo inoputika gasi. Kuburikidza nekutsinhana kusina kunanga kwekupisa, mvura yekupfapfaidza inobviswa neplate heat exchanger uye shongwe inotonhorera, kuitira kuchengetedza mvura uye kuderedza kubuda kwetsvina. Gasi risiri-conndensible (shoma shoma yemhepo, N2, mhepo uye sludge volatiles) inopfuura nemu demister. Chekupedzisira, iyo yekupedza inokonzeresa dhizaini fan inoburitswa kubva pakuomeswa system kuenda kune deodorization mudziyo.

Iyo inopisa sosi inodiwa inotemerwa kuve chiutsi, icho chinotorwa kubva kune inopisa yekuvharira pombi network yakavakirwa padyo nenzvimbo yekuita purojekiti. Mamiriro ekupa chiutsi kumanikidza kwe1.0MPa, tembiricha ye180 ℃ uye 2.5t / h.

2. Technical parameters yemidziyo mikuru yekuonda firimu kuomesa maitiro

Zvinoenderana nezvinodiwa zvepurojekiti iyi, iyo sludge yekugadziriswa kweseti imwe chete yesludge drying system inotarwa kuve 2.5t / h (maererano nehunyoro hwe80%), uye hunyoro hwematope hunoita 35%. Huwandu hwemazuva ese hwemadhaka ekuomesa firimu i60 t/d (zvichienderana nehunyoro hwe80%), iyo yakatemerwa evaporation kugona kweimwe nhete yekuomesa firimu i1.731 t/h, nzvimbo yekutsinhanisa kupisa kweimwe chete. mutete firimu dryer ndeye 50 m2, uye hunyoro hwemadhaka inlet i80%, uye hunyoro hwemadhaka ekubuda kwedhaka i35%. Iko kupisa kunopisa kweiyo yakaonda firimu dryer ine saturated steam, uye hunhu hwekupihwa kwehutsi hunotengeswa kunze kwenyika: tembiricha yehutsi i180 ℃, mhepo yemhepo ndeye 1.0 MPa, kushandiswa kwemhepo kweimwe nhete yefirimu yakaoma ndeye 2.33t / h, uye iyo nhamba yakaonda firimu dryer ndeye 2, imwe yekushandiswa kumwe chete.

Iyo saturated steam ye180 ℃ inotakurwa ichiendeswa kune mutsara wekuomesa kuburikidza nepiipi yekumanikidza, uye inoshandiswa senzvimbo yekupisa kupisa zvisina kunanga iyo semi-yakaoma sludge. Mvura iri mu semi-dry sludge inowedzera kubuda mumutsara wekuomesa. Zvinoenderana nezvinodiwa chaizvo zvechigadzirwa chesludge (kutanga uye kumira), iyo yekupedzisira sludge inogona kusvika 10% hunyoro hwemukati uye enda kune chigadzirwa chinotonhorera.

Kugadziriswa kweiyo linear dryer ndeye 0.769t / h (hunyoro hwemukati 35%), iyo yakatemerwa evaporation ndeye 0.214t / h, nzvimbo yekutsinhanisa kupisa i50 m2, hunyoro hwemadhaka inlet yelinear dryer ndeye 35%, mwando. Zviri mukati medhaka rekuburitsa i10%, iyo steam quality inlet parameters yelinear dryer: Tembiricha yeutsi i180 ℃, iyo dhizaini inosvika 1.0 MPa, kushandiswa kwechiutsi kwemutsetse mumwe chete wekuomesa i0.253 t/h, uye huwandu hwacho hwakashongedzerwa. ne1 set.

Mhando yemidziyo yemutakuri gasi condenser ndeye yakananga jekiseni hybrid condenser, ine mhepo inotora 3 500 Nm3/h, inopinza gasi tembiricha inosvika 95 ~ 110 ℃, yekubuda gasi tembiricha ye90~180 Nm3/h, uye yekubuda gasi. tembiricha ye55 ℃.

Iyo yemidziyo yemhando yeanotakura gasi inokonzeresa kudhirowa fan ndeyekumanikidza kwe centrifugal fan, iyo yakanyanya kusveta mhepo vhoriyamu i400 Nm3/h, mweya wemhepo uri 4.8 kPa, iwo emuviri maparamendi eanotakura gasi yepakati: tembiricha i45 ℃, humidity. iri 80% ~ 100% yemhepo inonhuhwirira gasi musanganiswa, imwe seti yekuomesa system inoshongedzerwa 1 seti.

Kugona kugadzirisa kwechigadzirwa chinotonhorera ndeye 1.8t / h, sludge inlet tembiricha i110 ° C, tembiricha yekubuda kwedhaka iri ≤45 ° C, nzvimbo yekutsinhanisa kupisa i20 m2, uye huwandu i1 unit.

3. Ongororo yekushandiswa kwesimba rehupfumi panguva yekumisikidza yakaonda firimu dryer

Mushure meinoda kusvika hafu yemwedzi yekumisikidzwa kamwe chete uye madhaka ekumisikidzwa kweiyo yakaonda firimu kuomesa process system, mhedzisiro ndeiyi inotevera.

Iyo dhizaini yekumisikidza kugona kweimwe yakaonda firimu yakaoma muchirongwa ichi ndeye 60 t/d. Parizvino, avhareji yekunyorova madhaka ekurapa panguva yekutumwa i50 t/d (hunyoro hwemukati i79%), iyo yasvika 83% yeyakagadzirwa sludge wet base treatment scale uye 87.5% yezvakagadzirwa sludge dry base treatment scale.

Avhareji yehunyoro hwesemi-dry sludge inogadzirwa neyakaomesesa firimu iri 36%, uye hunyoro hwesemi-yakaoma sludge inotengeswa kunze neiyo linear dryer i36%, iyo inoenderana neinongedzo kukosha kweiyo. chigadzirwa chigadzirwa (35%).

Yakayerwa neyekunze yakazadzwa mita yeutsi musludge drying workshop, iyo yakazara chiutsi chinodyiwa i25 t/d, uye theoretical yakazara zuva nezuva kupisa kushandiswa kwelatent kupisa kwemhepo inopisa i25 t×1 000×2 014.8 kJ/kg÷4.184 kJ =1.203 871 9×107 kcal/d. Avhareji yemazuva ese evaporation mvura yekuomesa system ndeye (50 t × 0.79)-[50 t × (1-0.79)] ÷ (1-0.36)×1 000=23 875 kg/d, Zvadaro unit kupisa kushandiswa kwe sludge drying system is 1.203 871 9×107÷23 875=504 kcal/kg mvura yakapfava; Nekuti iyo sludge drying system iri pasi pekushandurwa kwekunyorova kwehunyoro hwemvura, kunaka kwekunze kweutsi, uye hunhu hwesemi-yakaoma sludge chigadzirwa chekutakura zvigadzirwa zvegranularity zvinodiwa uye zvimwe zvinhu, zvinodikanwa kukwirisa kukosha kweakasiyana akasiyana. mune ramangwana rekushanda kwekuedza kwenguva refu, kuitira kuti mupfupise akanakisa ekushandisa mamiriro uye ehupfumi simba rekushandisa index yehurongwa.